Timeline

Welcome to the UTIAS History Microsite! Created in honour of the 75th Anniversary of the founding of UTIAS, this microsite documents UTIAS’s history of excellence. It not only shows the foundation of excellence upon which UTIAS was built, but it shows the continuum of excellence that has kept UTIAS at the forefront of aerospace and robotics research.

The blog section is a repository for stories about UTIAS. And, we want to hear what you have to say, so you are invited to submit your stories! These can be simply memories or anecdotes about your time at UTIAS, stories about how UTIAS influenced your life path, or stories from your career years.

You will find the submission button in the blog section. Once you submit a story, it will be reviewed before it is posted.

This microsite is a curated work in progress designed for you to discover something new every time you visit. So, bookmark us, put your glasses on, fasten your seatbelt and get ready to go down those rabbit holes we promised!

1940s

1949

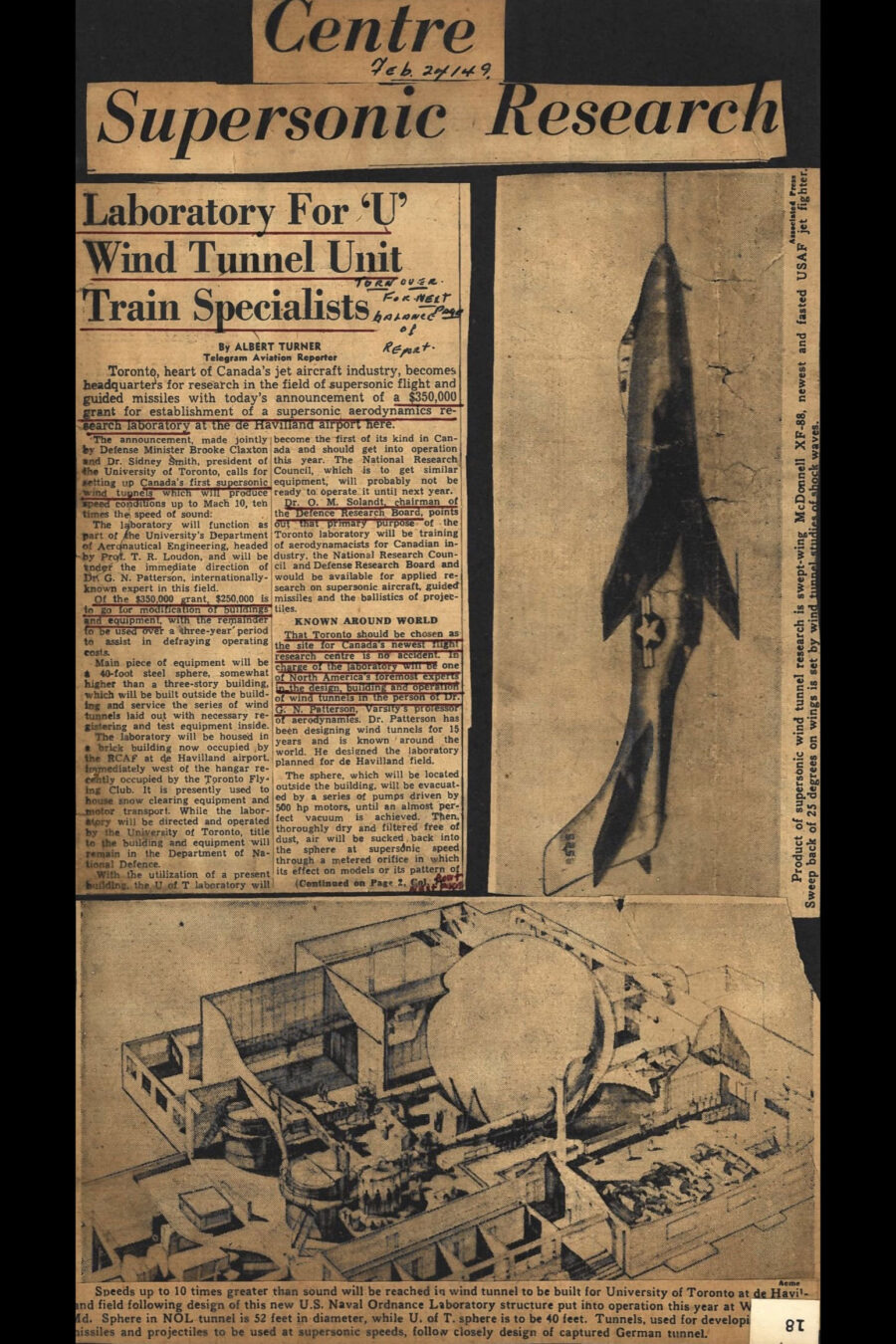

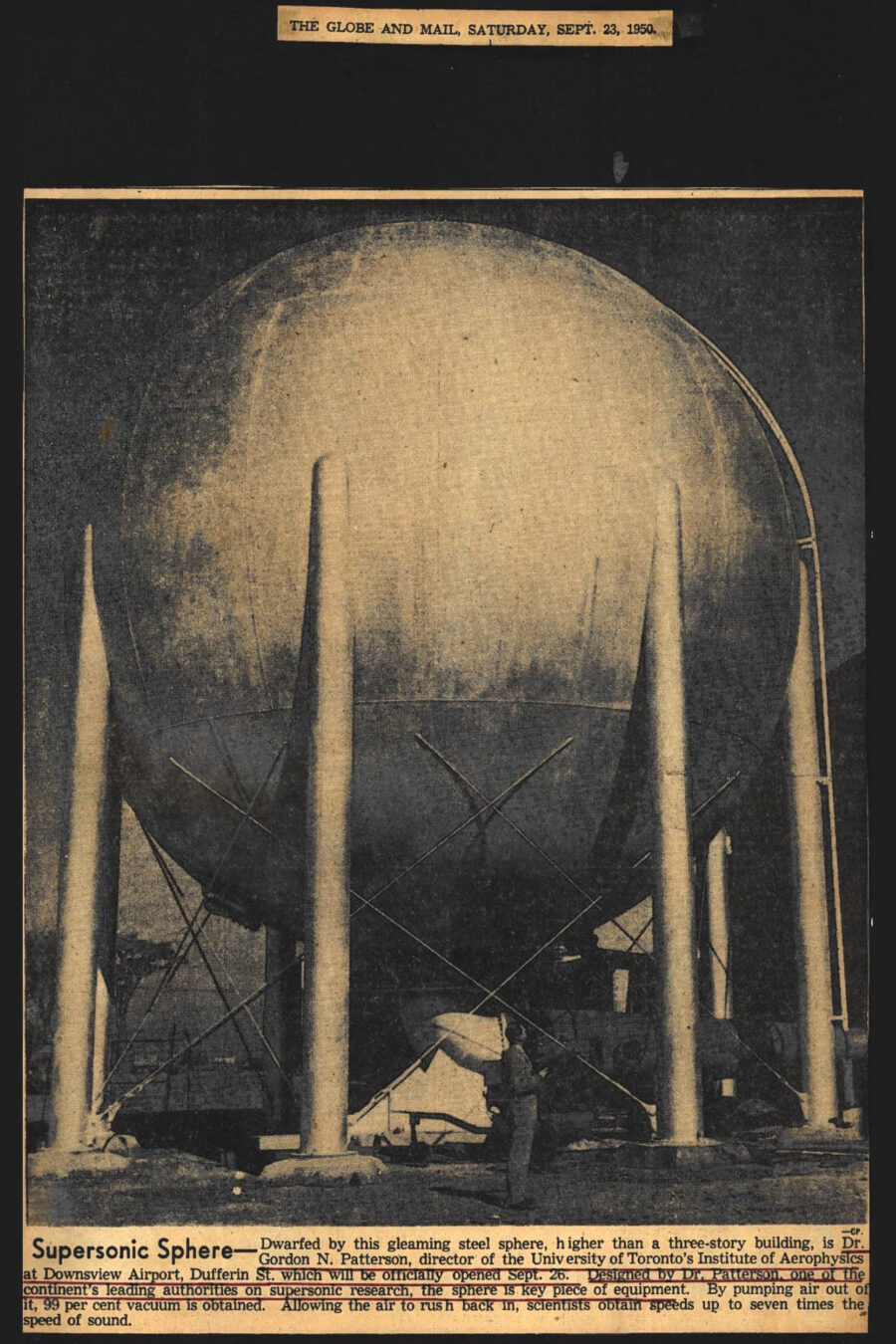

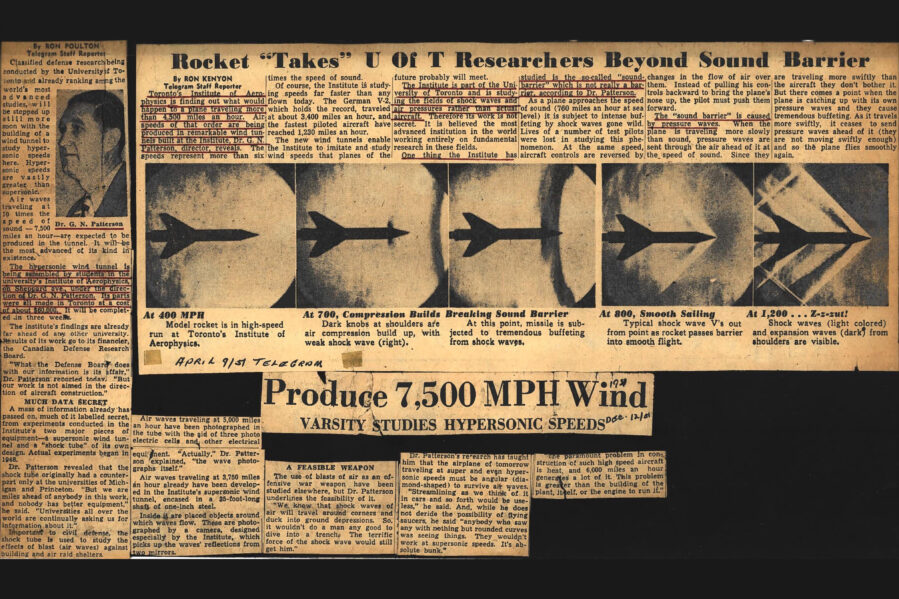

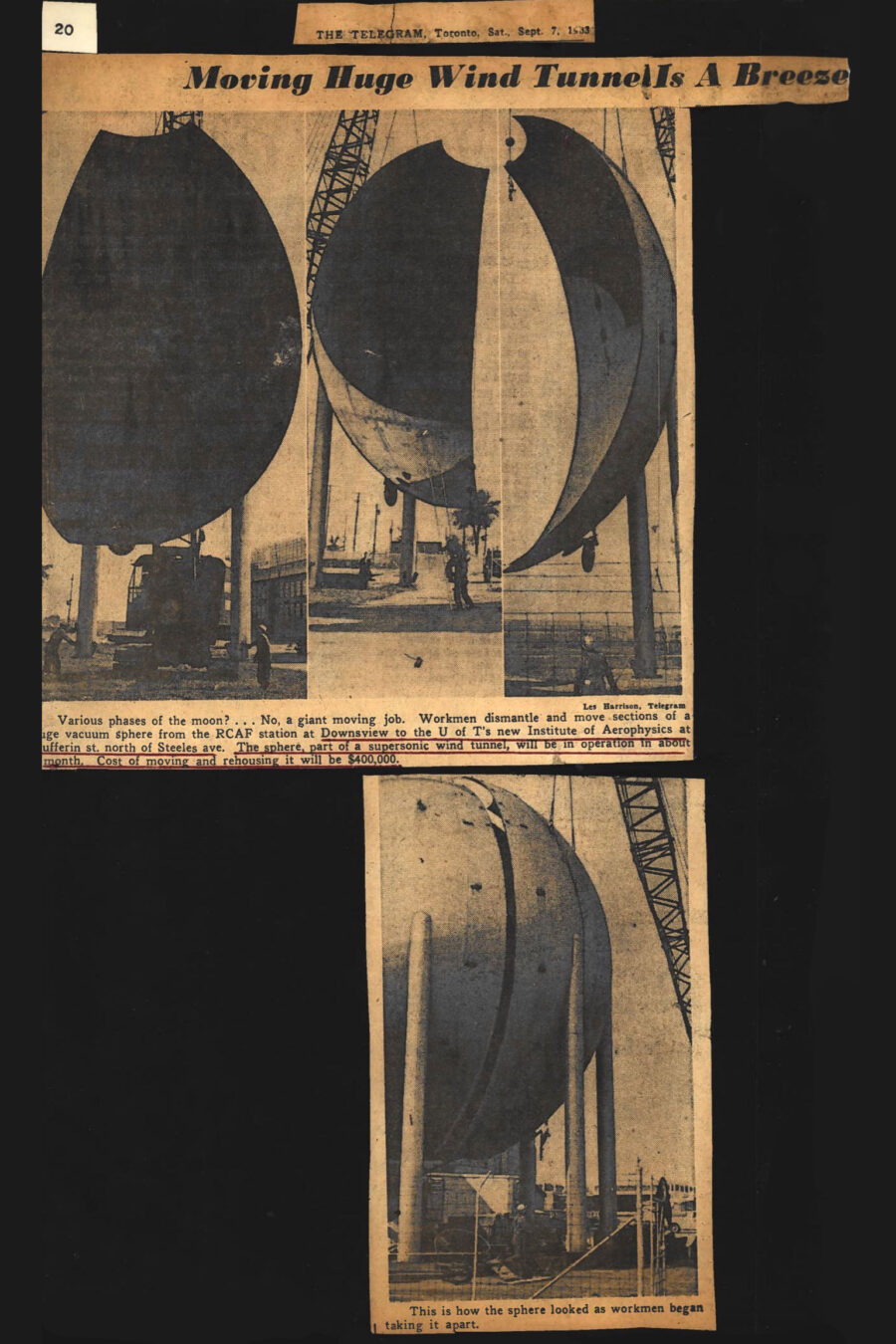

1949 April 1 – The Institute of Aerophysics is established with substantial government support, with new facilities at Downsview airport that opened in September 1950. It absorbed the Department of Aeronautical Engineering that had been established on 1 October 1946. Both divisions were headed by Gordon Patterson, who created a leading centre for aerospace studies with an advanced supersonic wind tunnel. From Heritage U of T.

1950s

1955

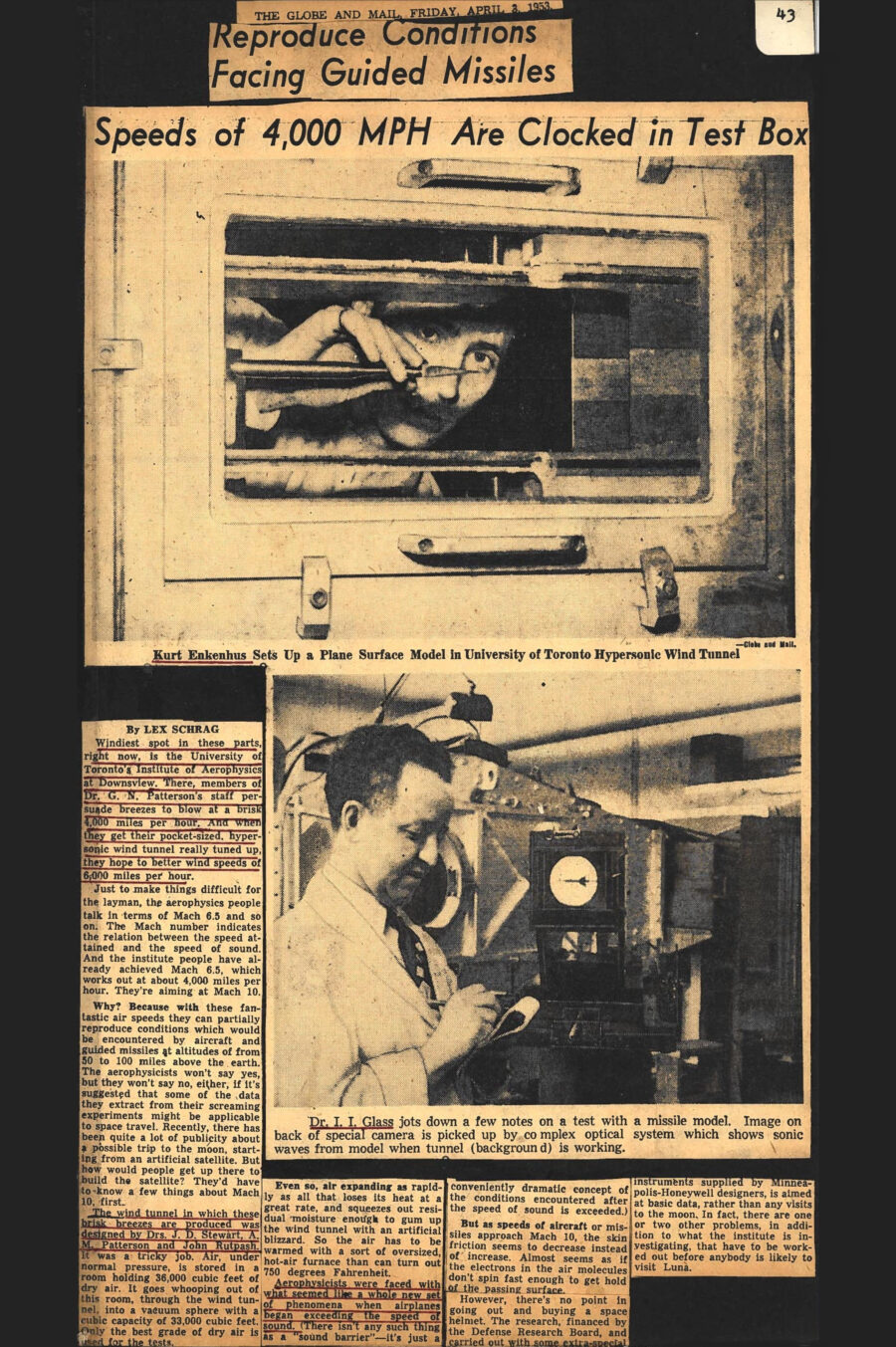

Travelling into space...

1956

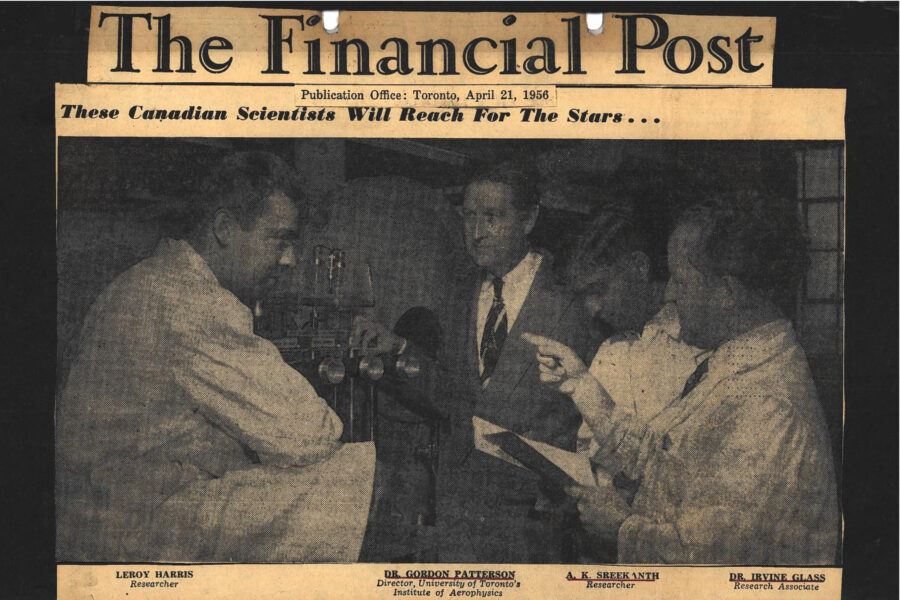

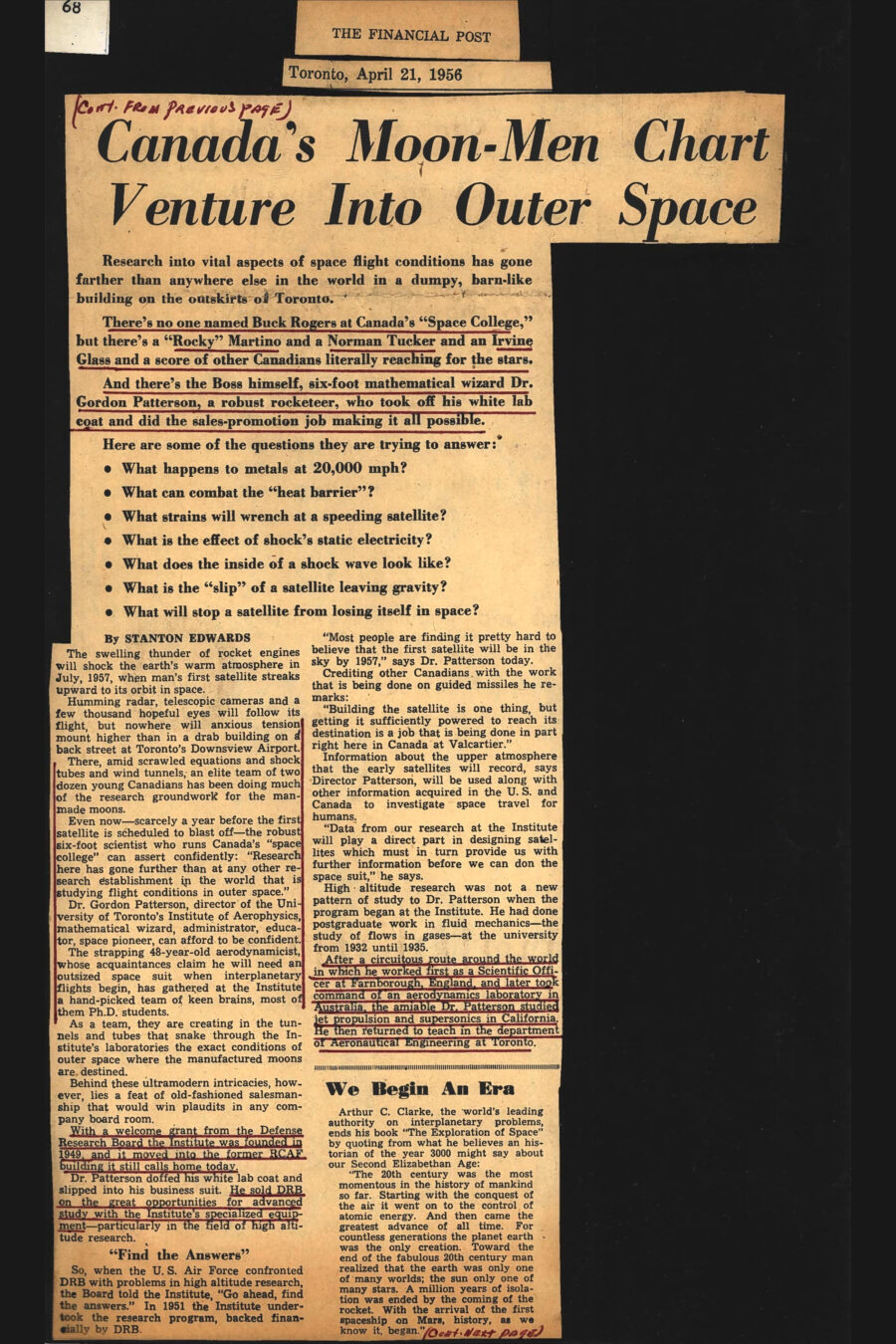

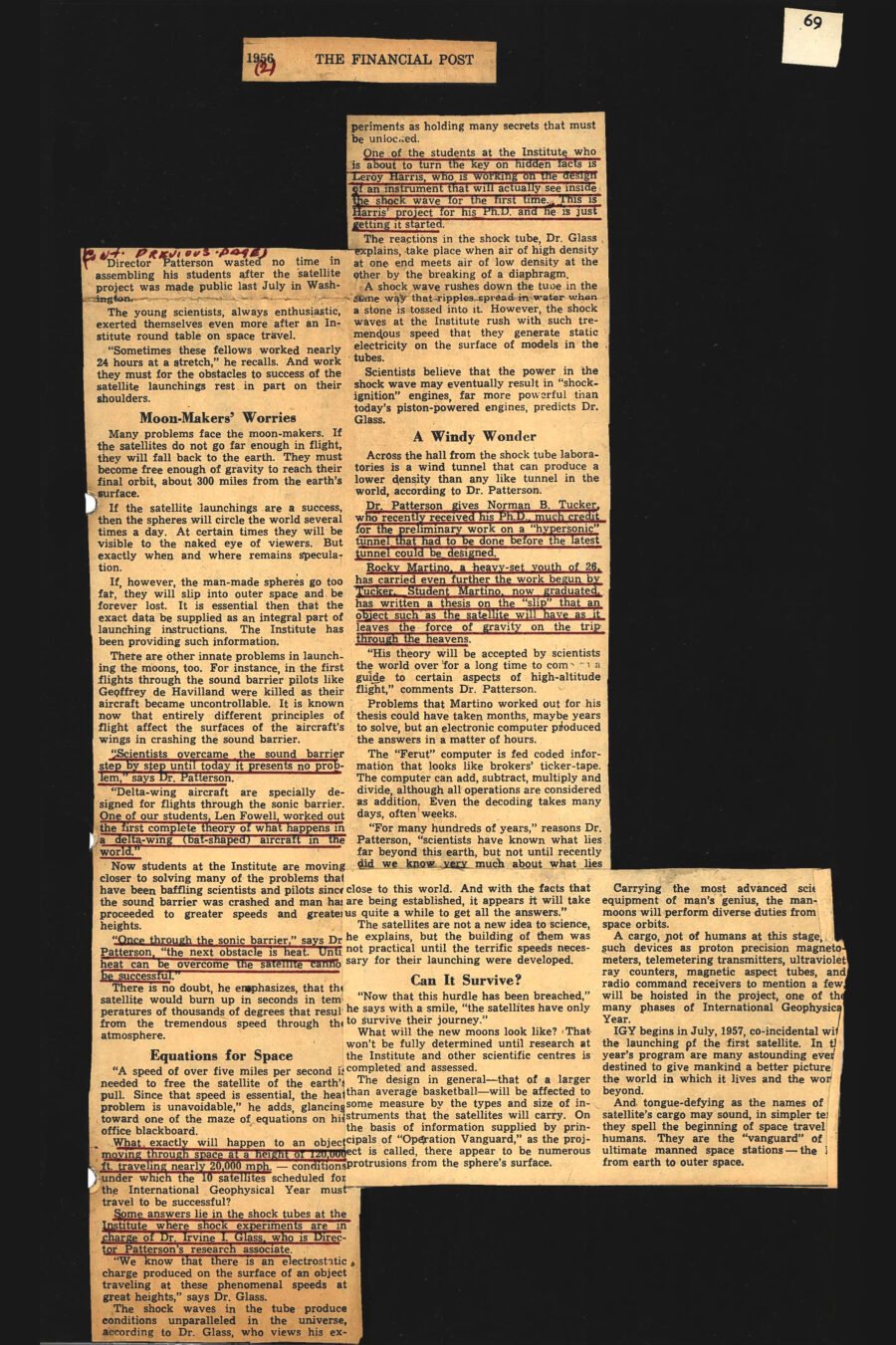

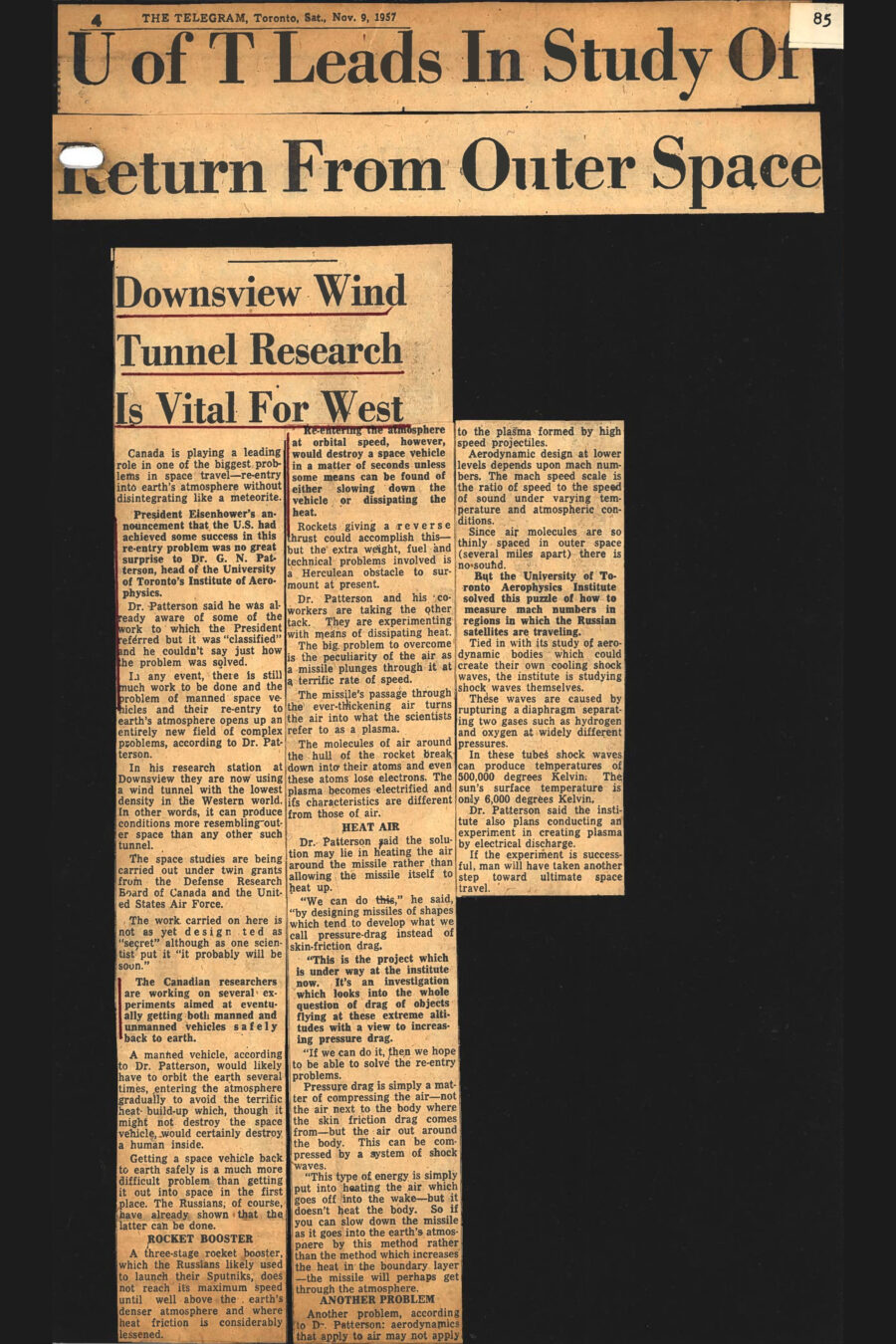

Canadian scientists reach for stars... [Material republished with the express permission of: Financial Post, a division of Postmedia Network Inc.]

1958

Other worlds might be home of weird monsters (while Canadian scientists race to the moon)...

1959

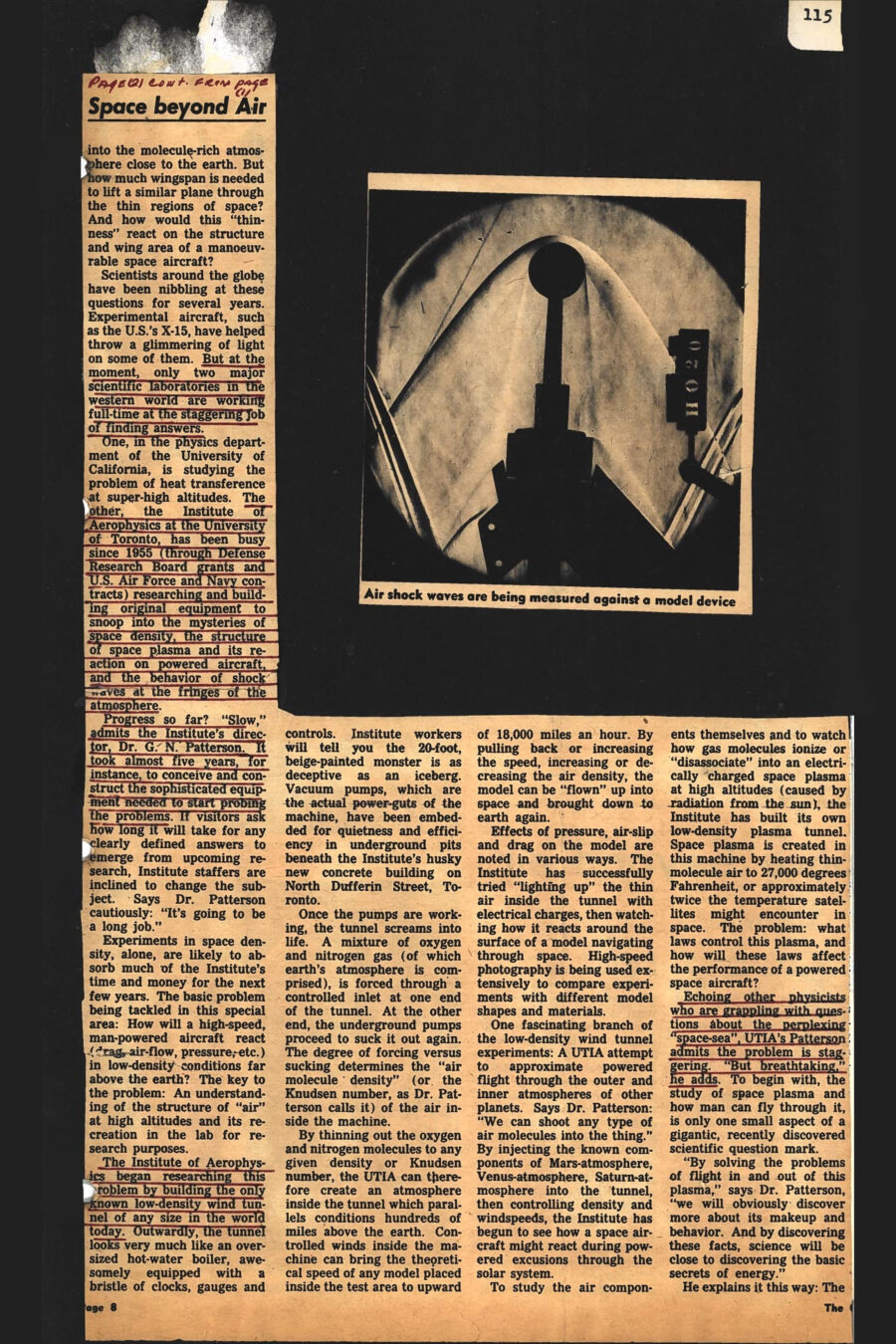

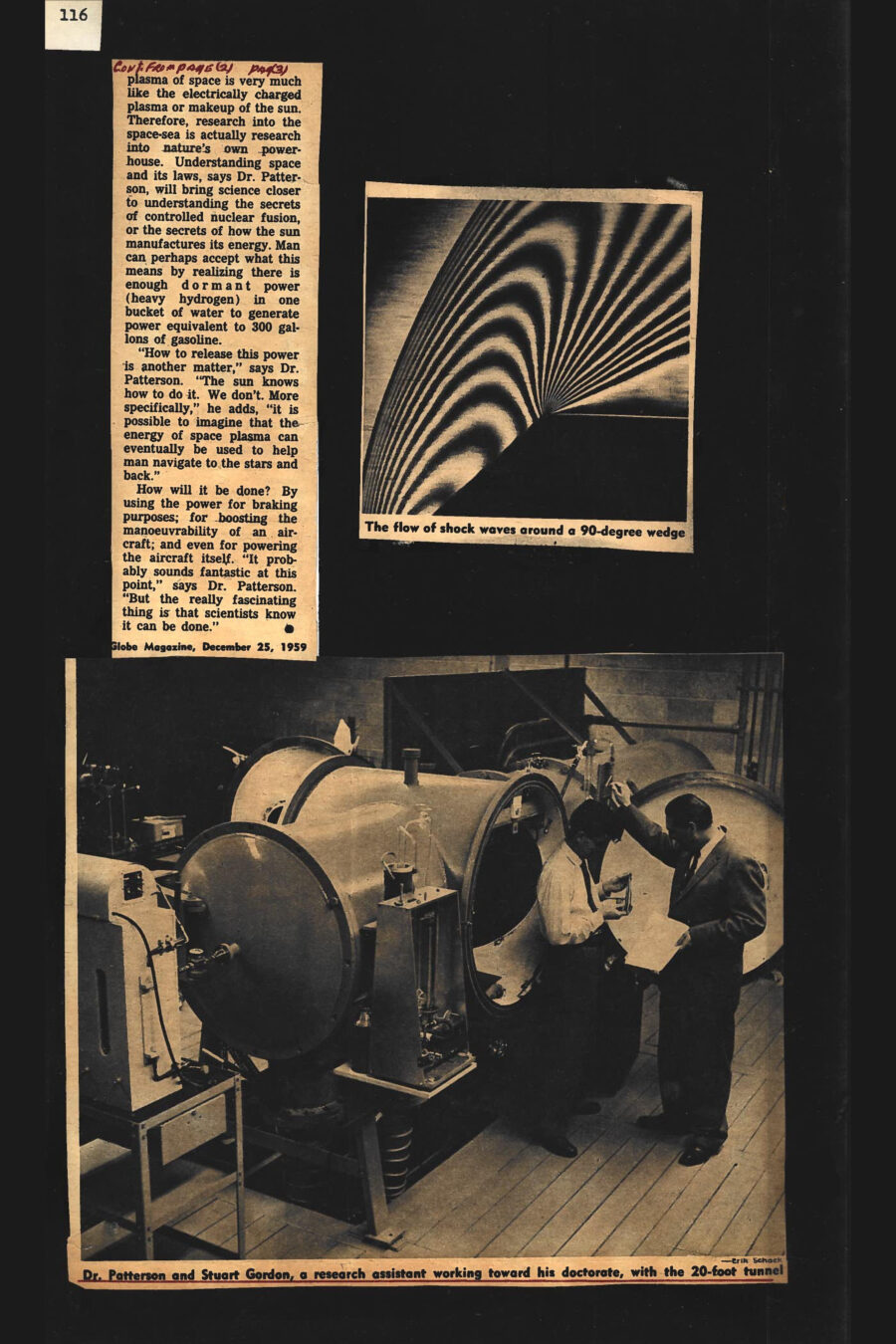

The wonders of the space beyond air.

1960s

1961

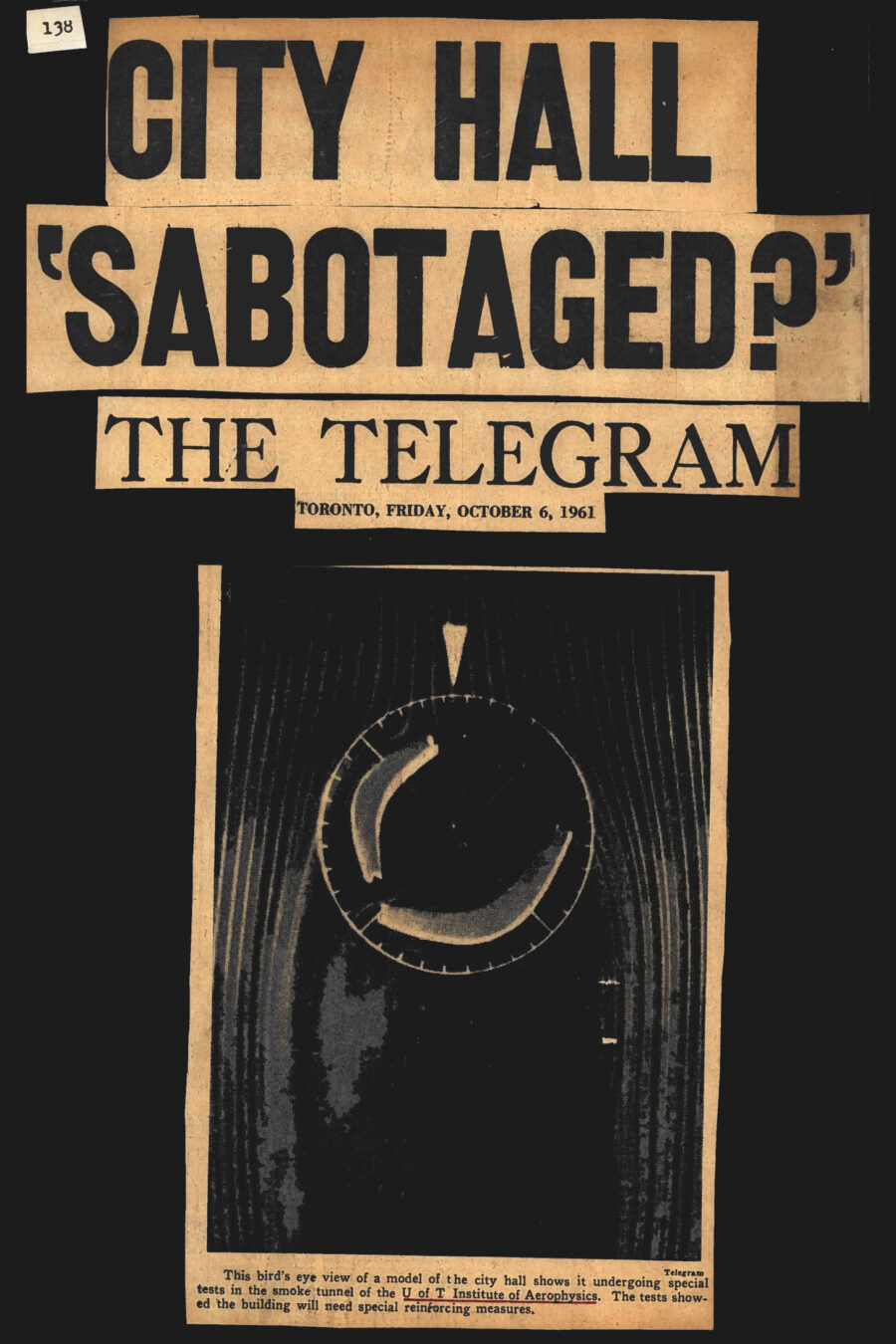

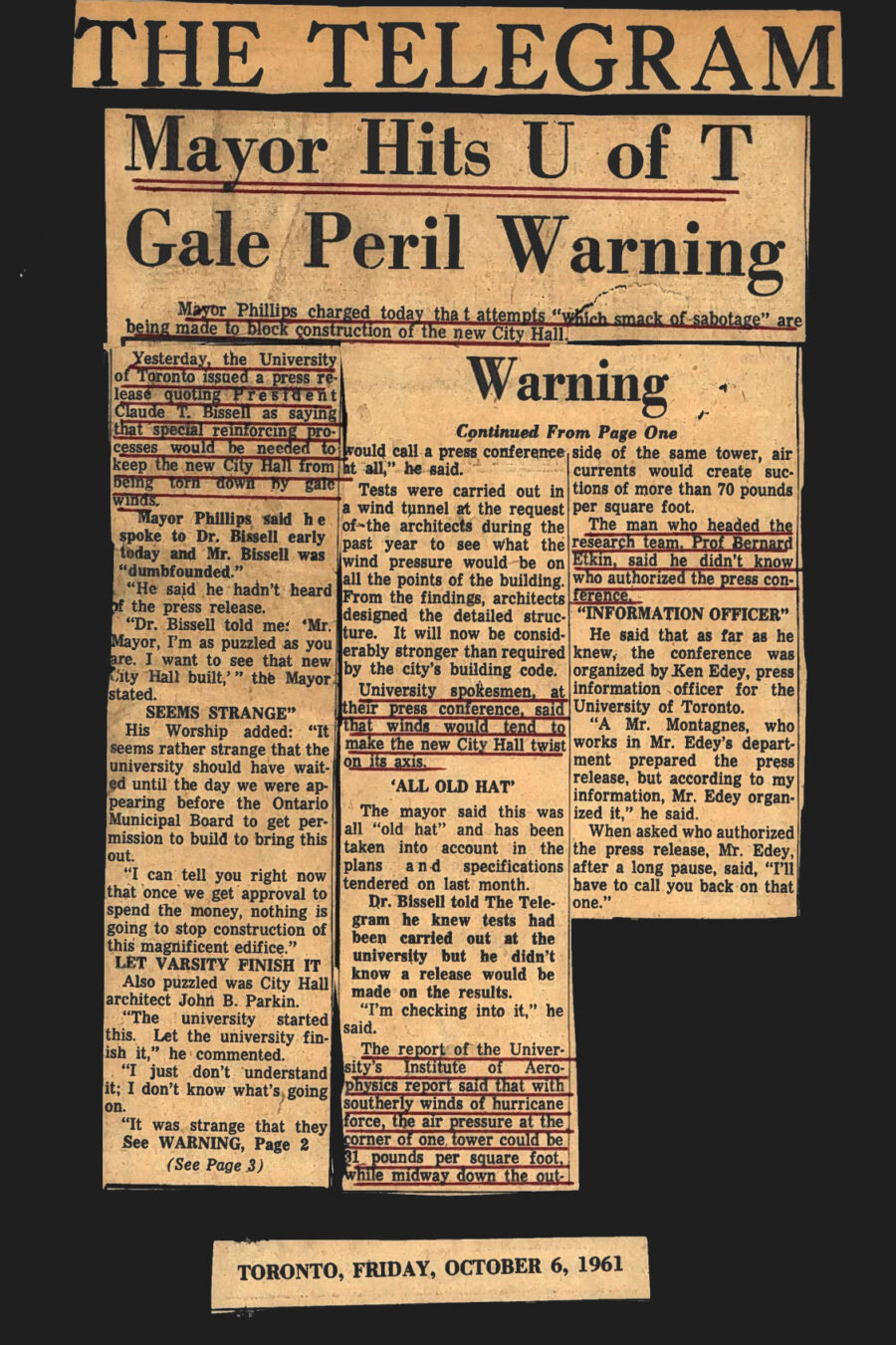

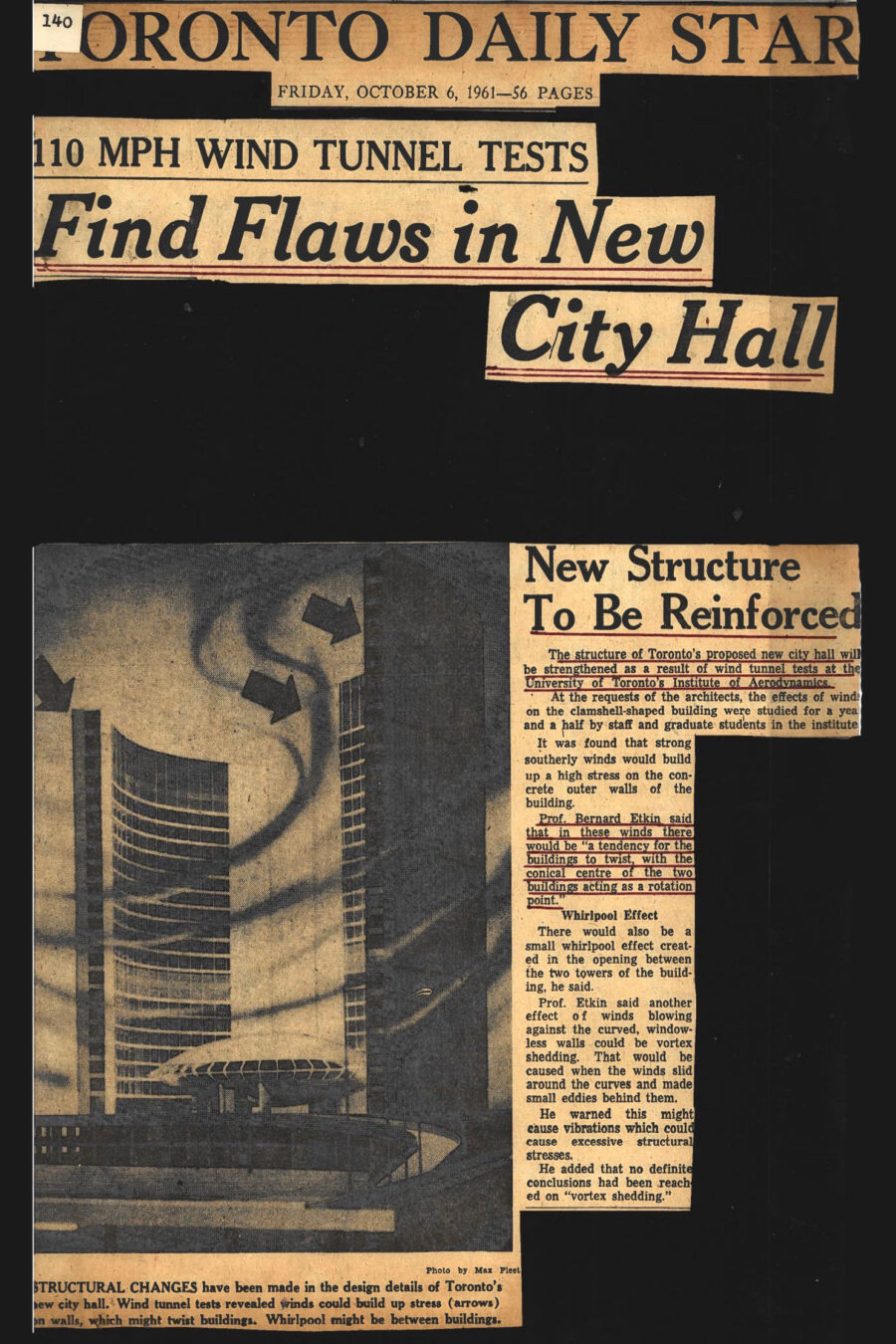

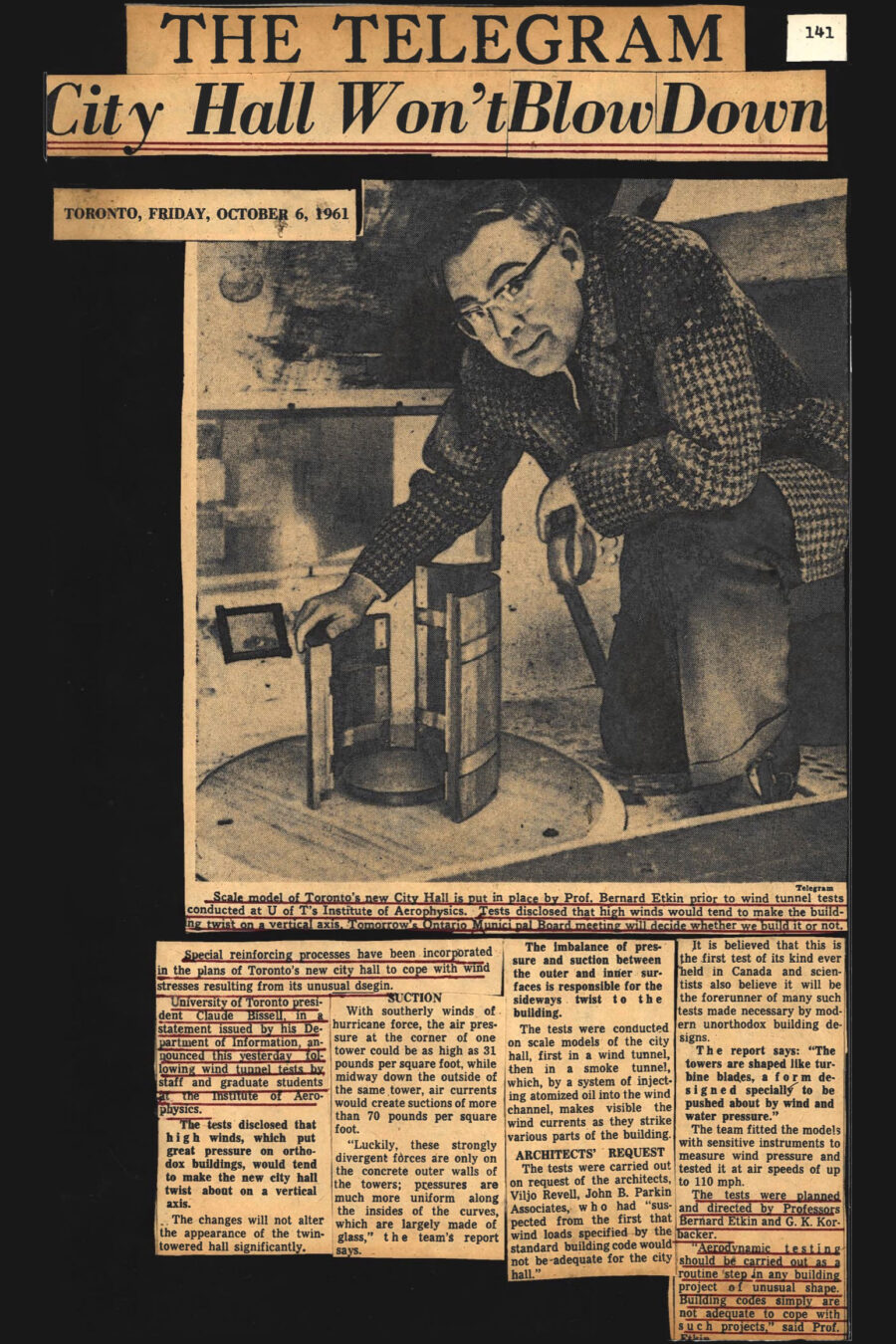

The measurement of the pressure distributions on a model of the proposed new City Hall in our subsonic tunnel in 1960 was probably the first wind engineering investigation of its kind in Canada. The staff members involved were Etkin and Korbacher, and the students were Karl Dau, Ron Chisholm, Bob Grenda, and George Kurylowich.

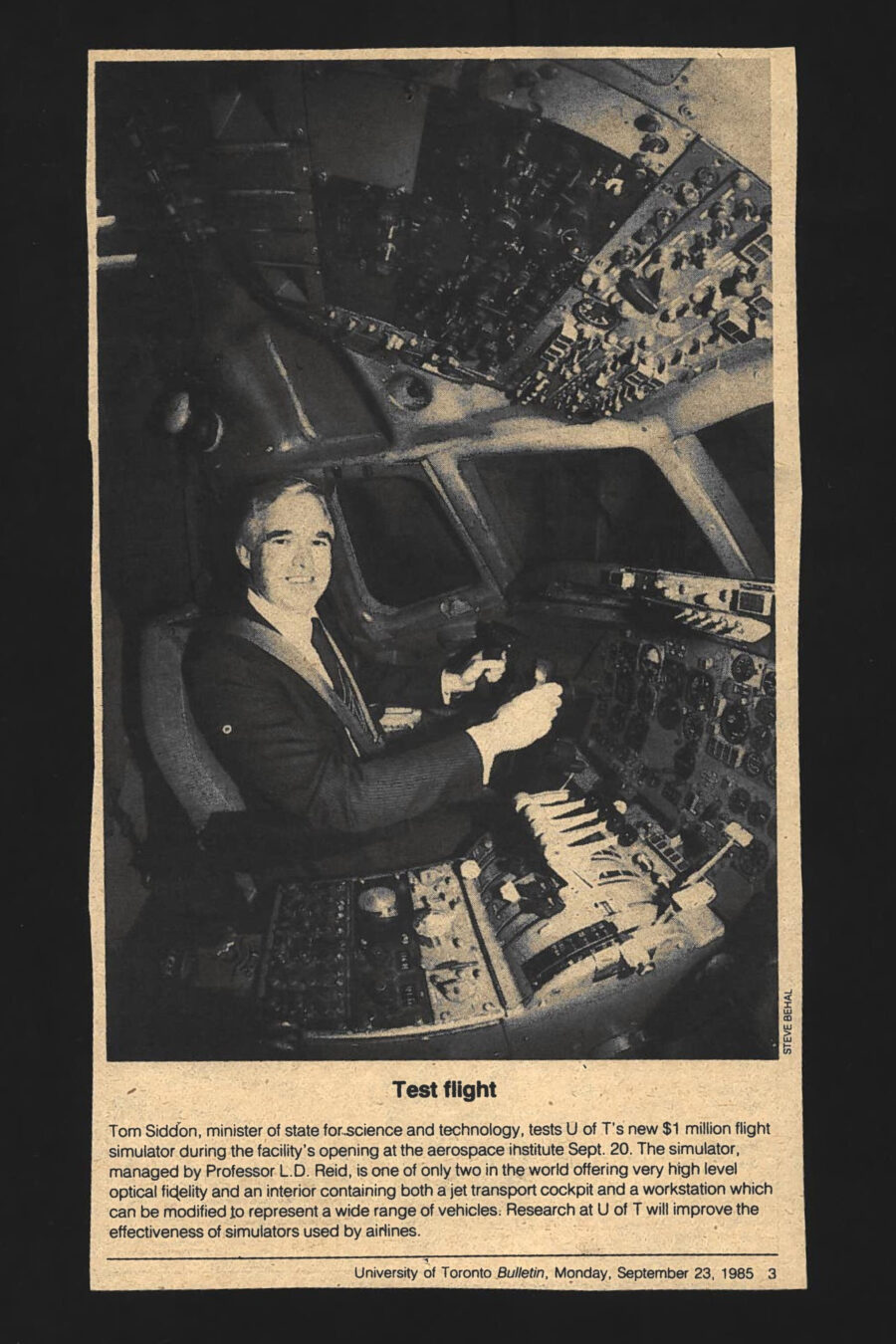

Our tests showed that the structure of the original building, as designed by Revell, the Finnish winner of the international design competition, was inadequate. It had very little torsional stiffness, and the buildings, acting like turbine blades, have large torsional moments. The structure, and the external shape, had to be extensively modified as a result.

When our findings were, after a year or so of silence, finally made public at a news conference all hell broke loose. The mayor Nathan Phillips, whose pet project the city hall was, called Sidney Smith and accused him of trying to sabotage his city hall. You see the problem was that our public relations office had timed the press conference to occur just before the Ontario municipal board was to meet to approve the project! But as you see, the City Hall did get built!

From Prof Etkin’s GNP Lecture 1989.

1963

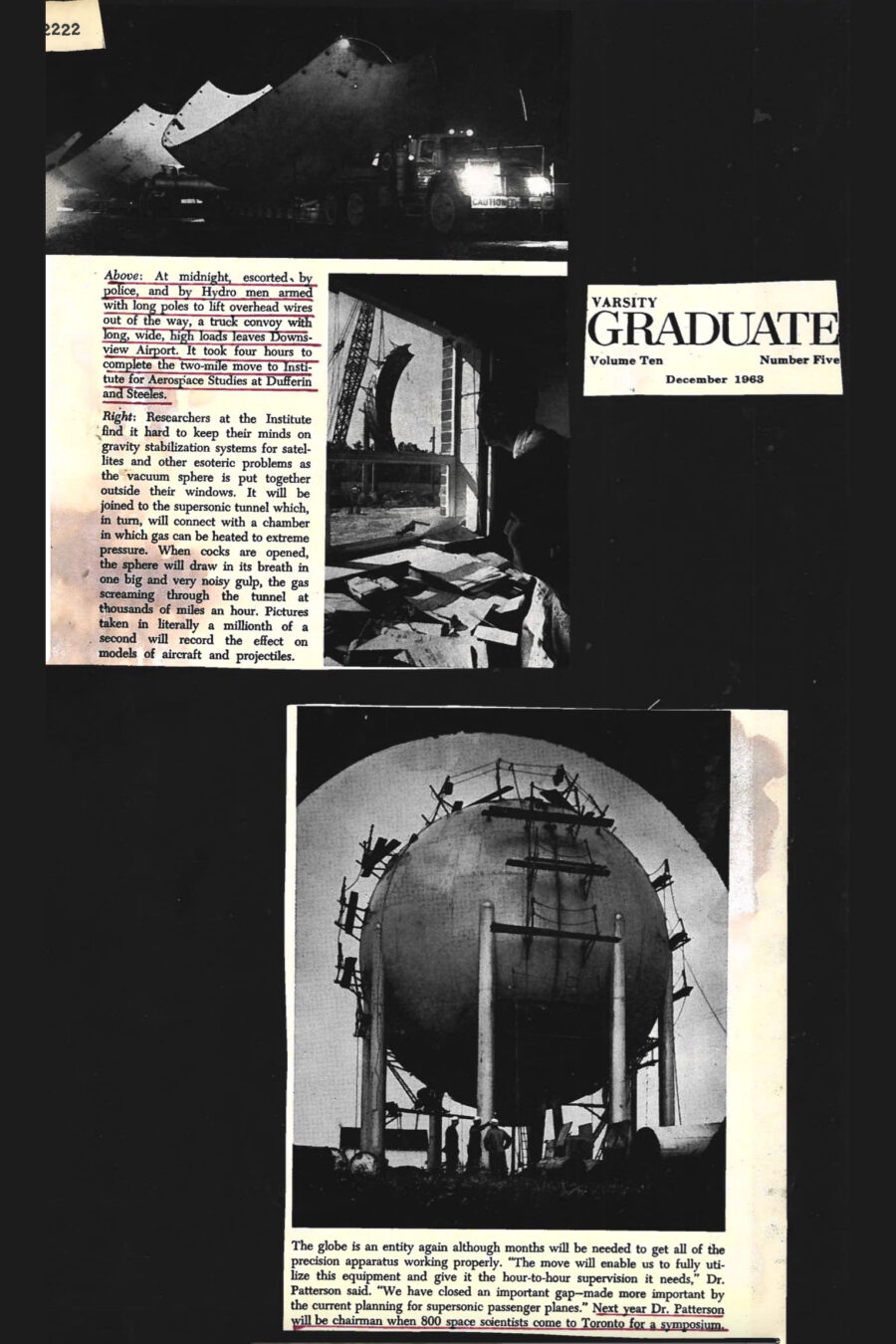

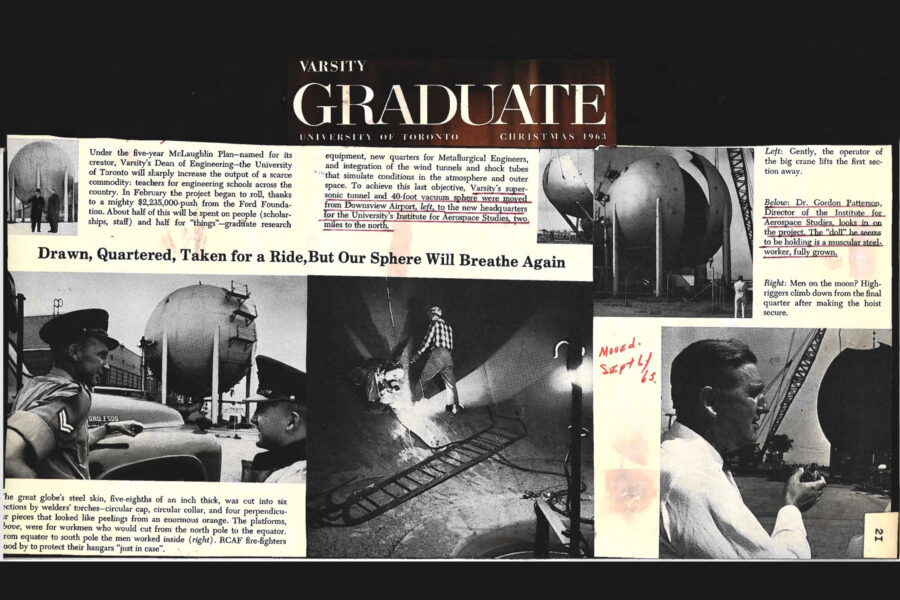

The 40 ft diameter sphere/wind tunnel finally moves to the new UTIAS location.

1963

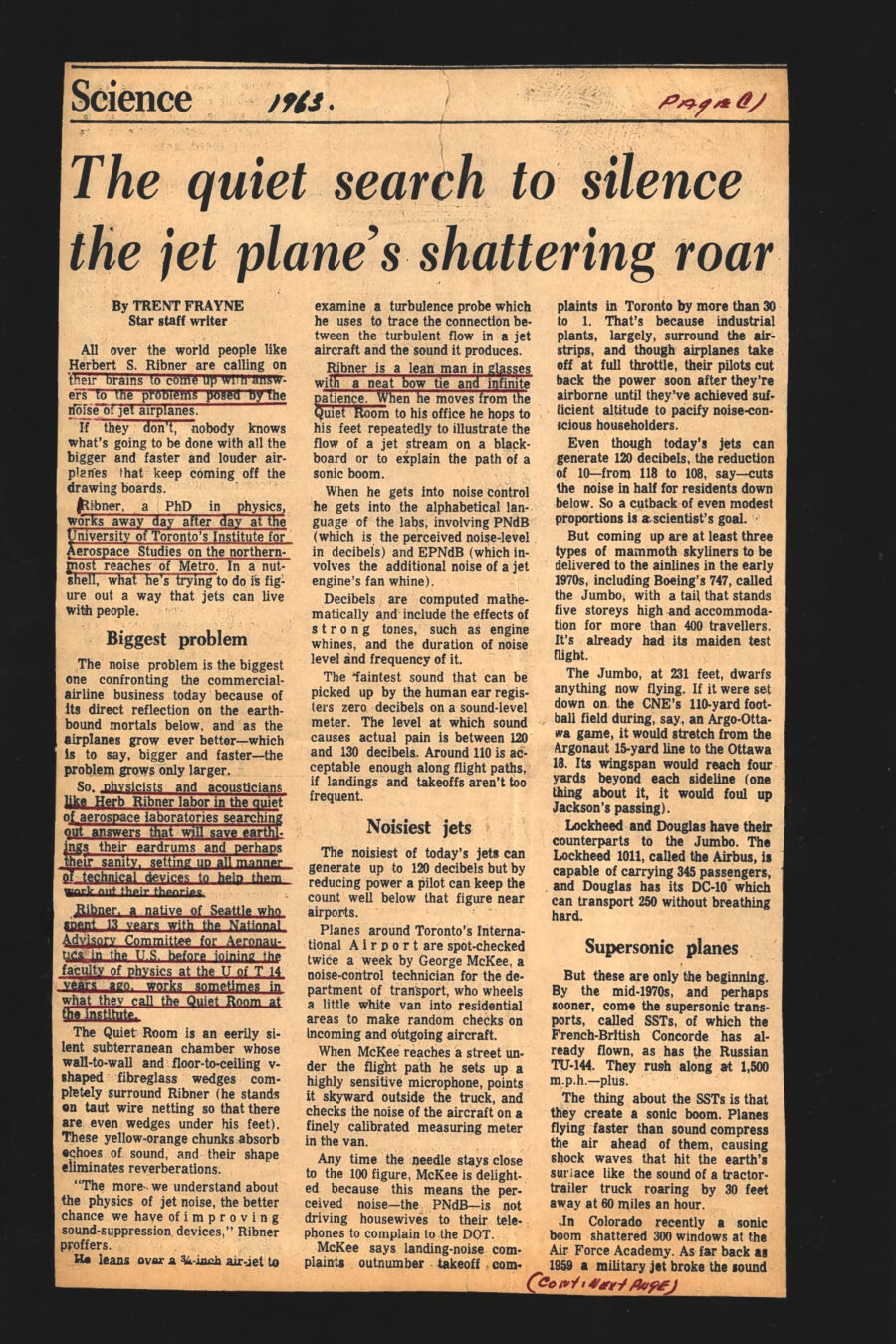

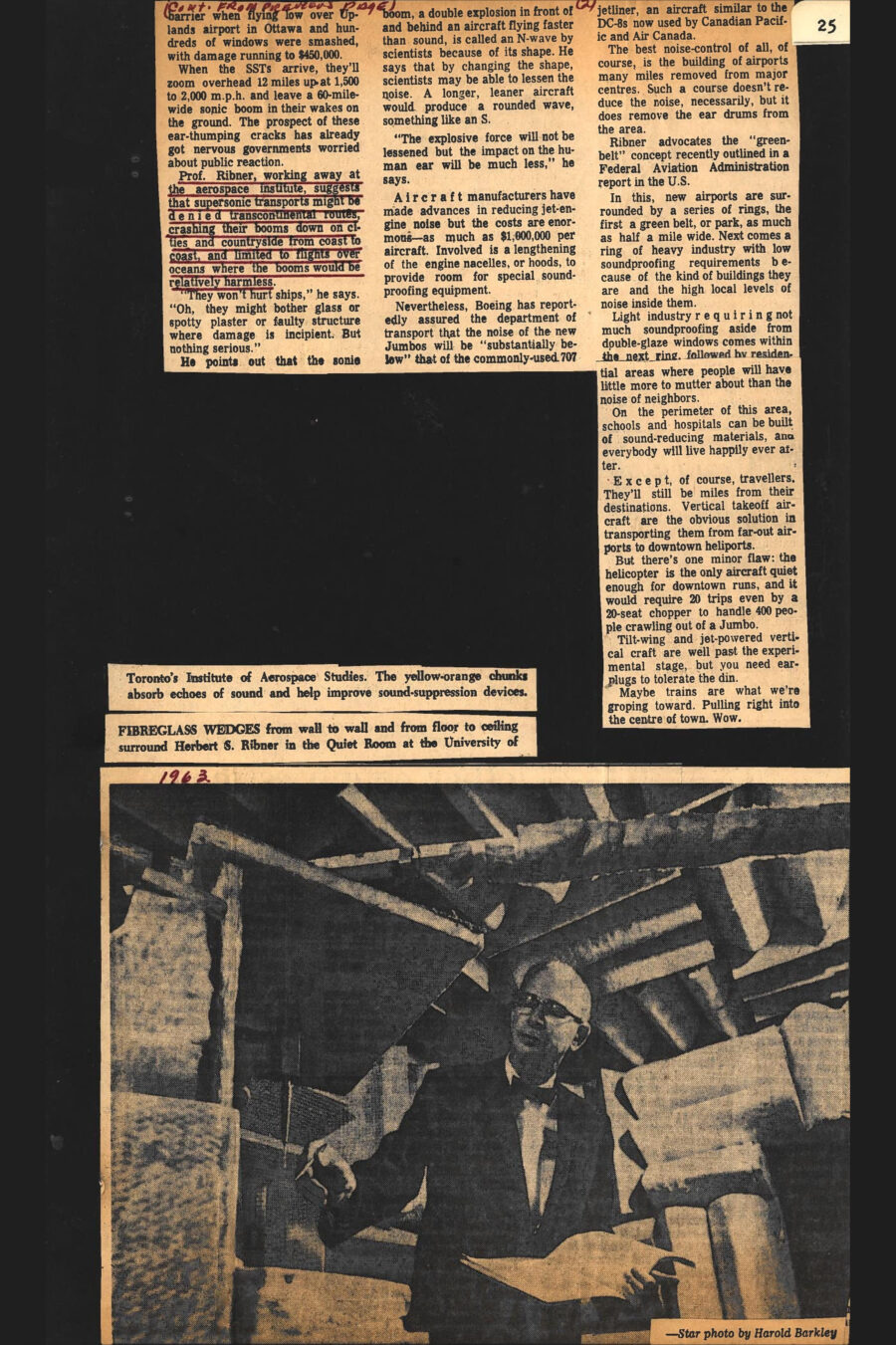

Professor Ribner's quiet search to silence the jet plane's shattering roar.

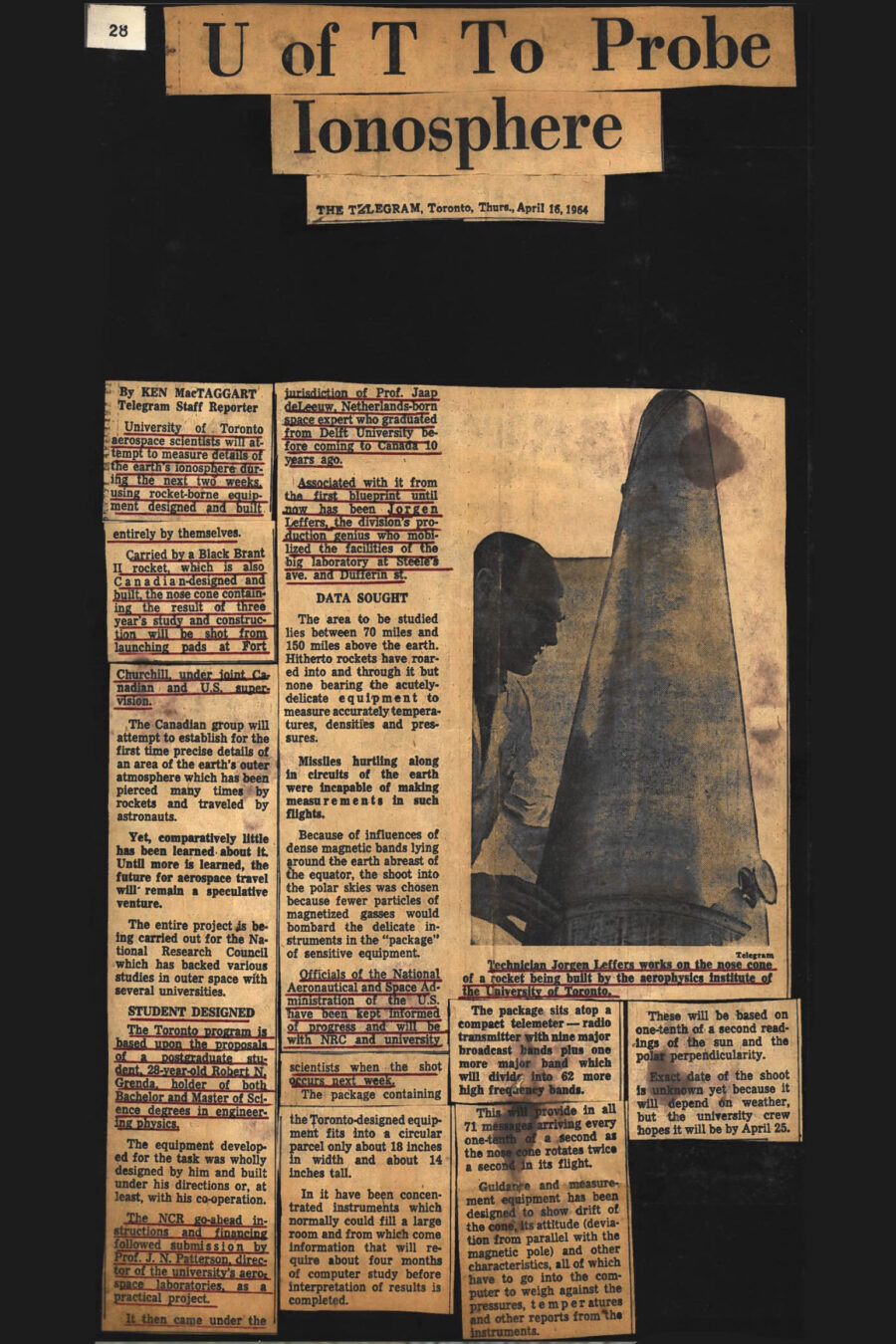

Year 1964 The Rocket Program

1965

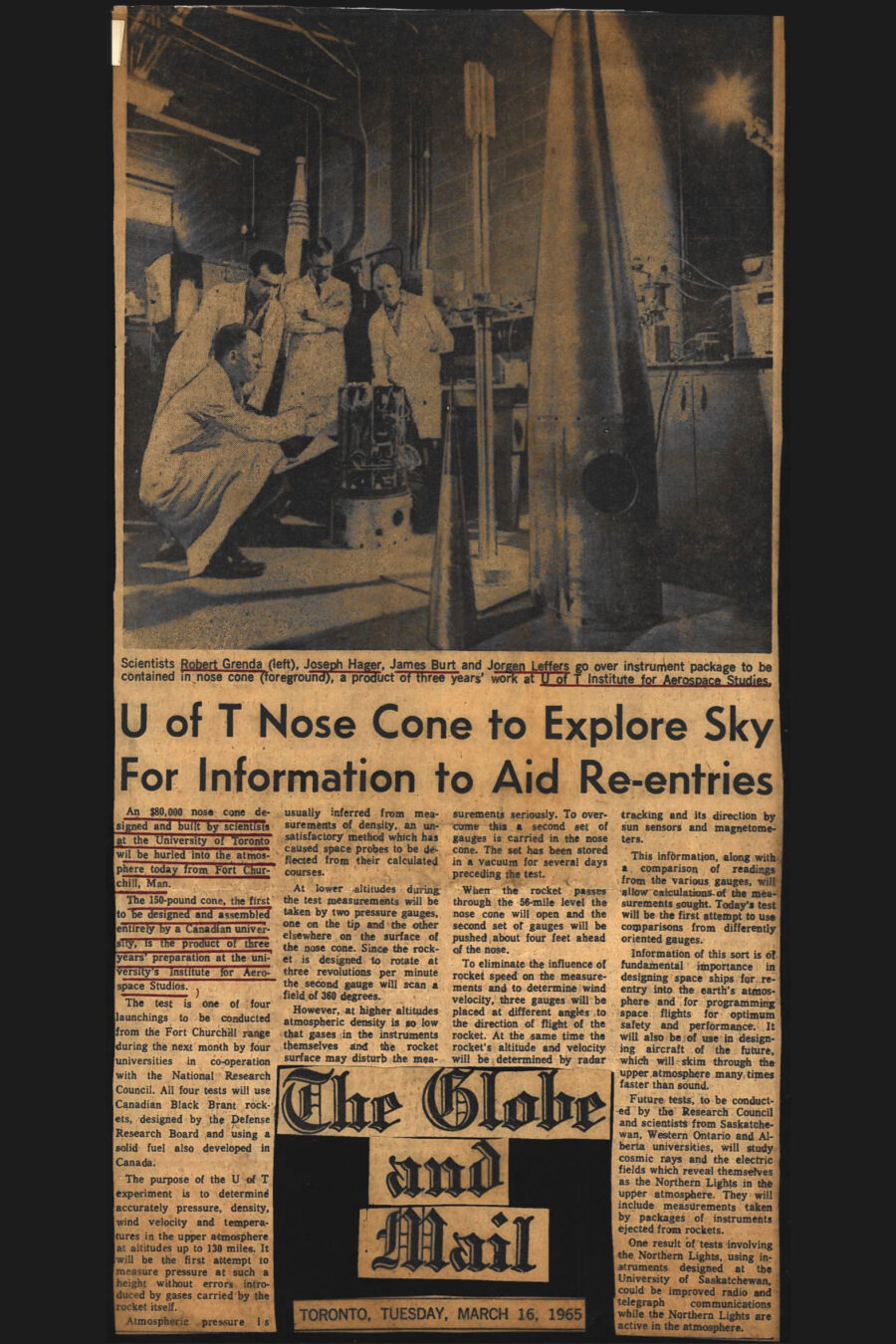

Rocket Program Part 1: For about 20 years, from 1962 to 1982, UTIAS participated in a most challenging real-world enterprise, the measuring of atmospheric density and temperature at heights above 100 kilometres. Led by Prof. J. de Leeuw, the team included Bob Grenda, Bill Davies, Jake Unger, and Jorgen Leffers. This group designed, fabricated, calibrated and tested most of the components that went into the rocket nose cones that were used. They were launched by black Brant rockets from NRC's launch facility at Fort Churchill, Ontario. The techniques were an evolution of what had been done in the low density laboratory at UTIAS.

It was a major challenge to develop complex hardware that would be sufficiently robust to be prepared and calibrated in the laboratory, then shipped to the launch site to work perfectly three months later without further adjustment. Moreover, to recover the payload, it had to survive the re-entry, heat load and parachute landing. All these challenges were met successfully and the final package was flown and recovered in usable form for 11 flights.

From Prof Etkin’s GNP Lecture 1989.

1965

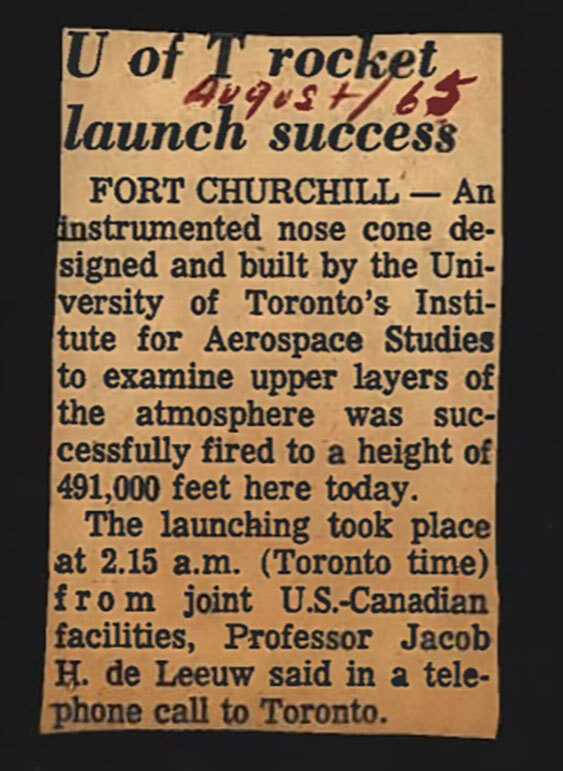

Rocket Program Part 2: Instrumented nose cone designed by UTIAS is successfully launched from Fort Churchill.

1967

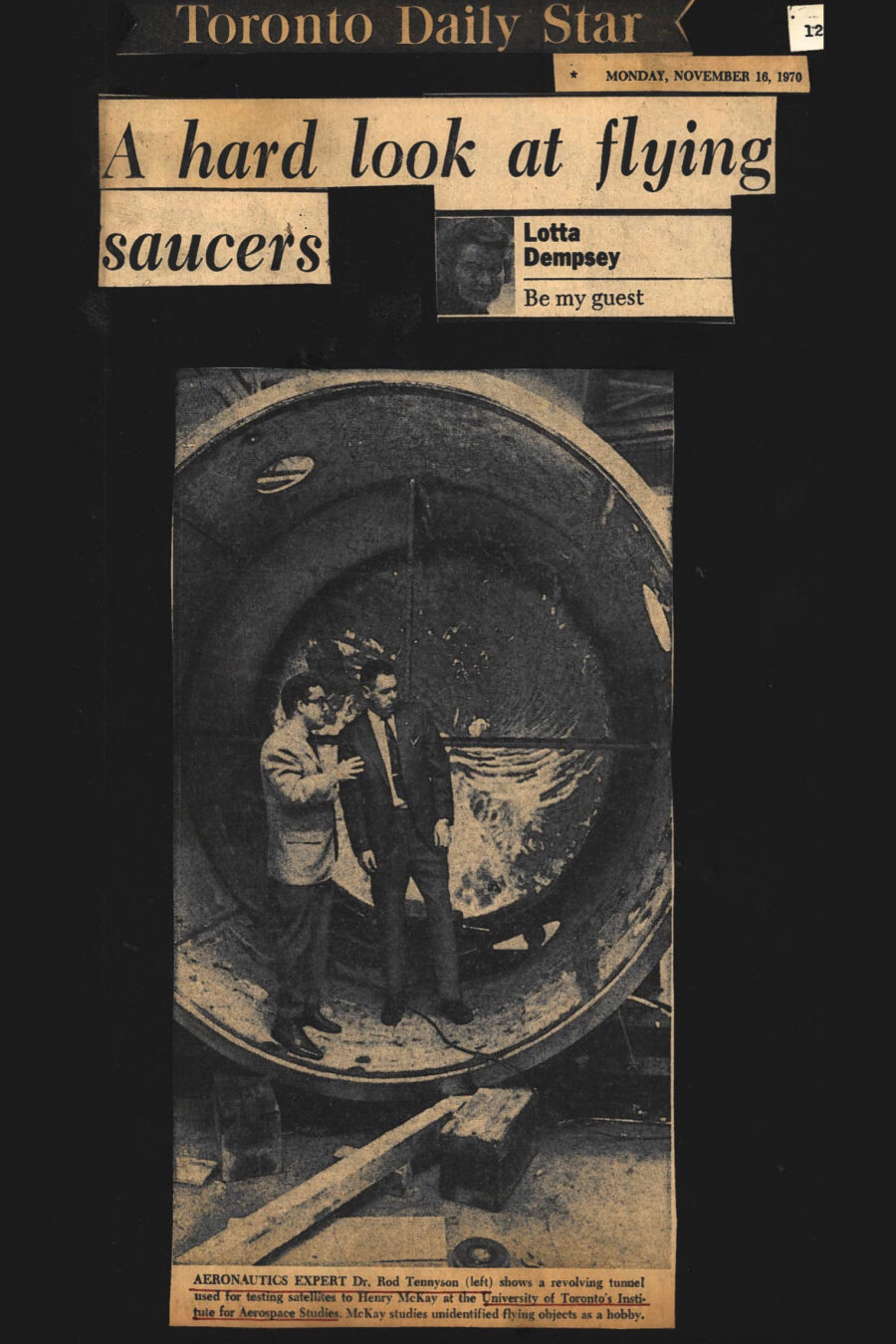

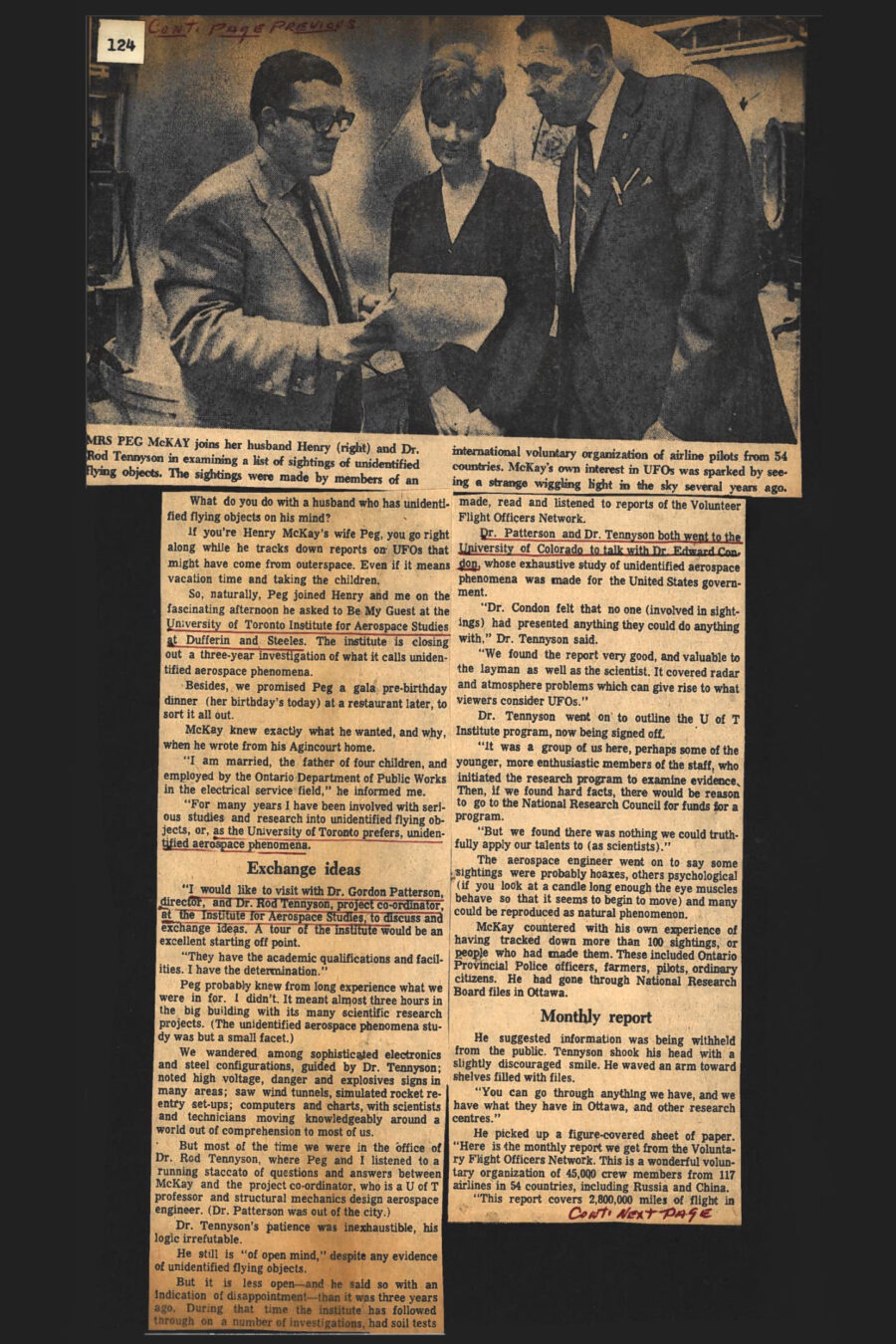

In the 1960s, UFO sightings around the world increased exponentially, with many occurring in Canada. In 1967, responding to the growing interest in UFOs, Dr. Patterson established a core of aerospace scientists to investigate sightings in Canada. Prof. Rod Tennyson led the group and was joined by Professors Stan Townsend and Ray Measures.

Read Prof. Tennyson’s account of their UFO investigations in our blog. And, read about the wrap-up of the UFO project in the 1970 Timeline entry.

1970s

1970

In 1970, after 3 years of inconclusive investigations, the UTIAS UFO project wraps up.

1974

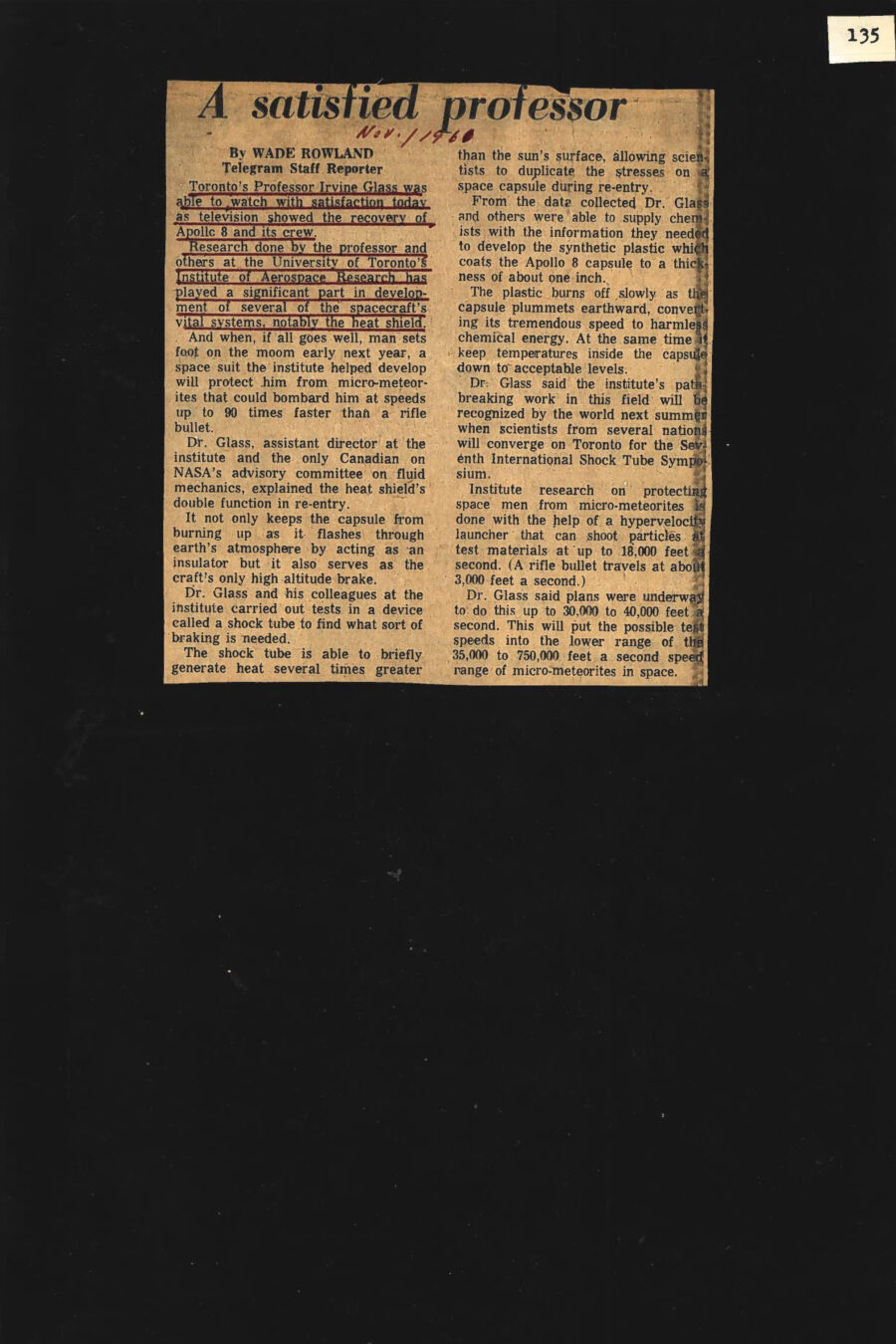

Professor Glass and the impact of shock waves.

1980s

1981

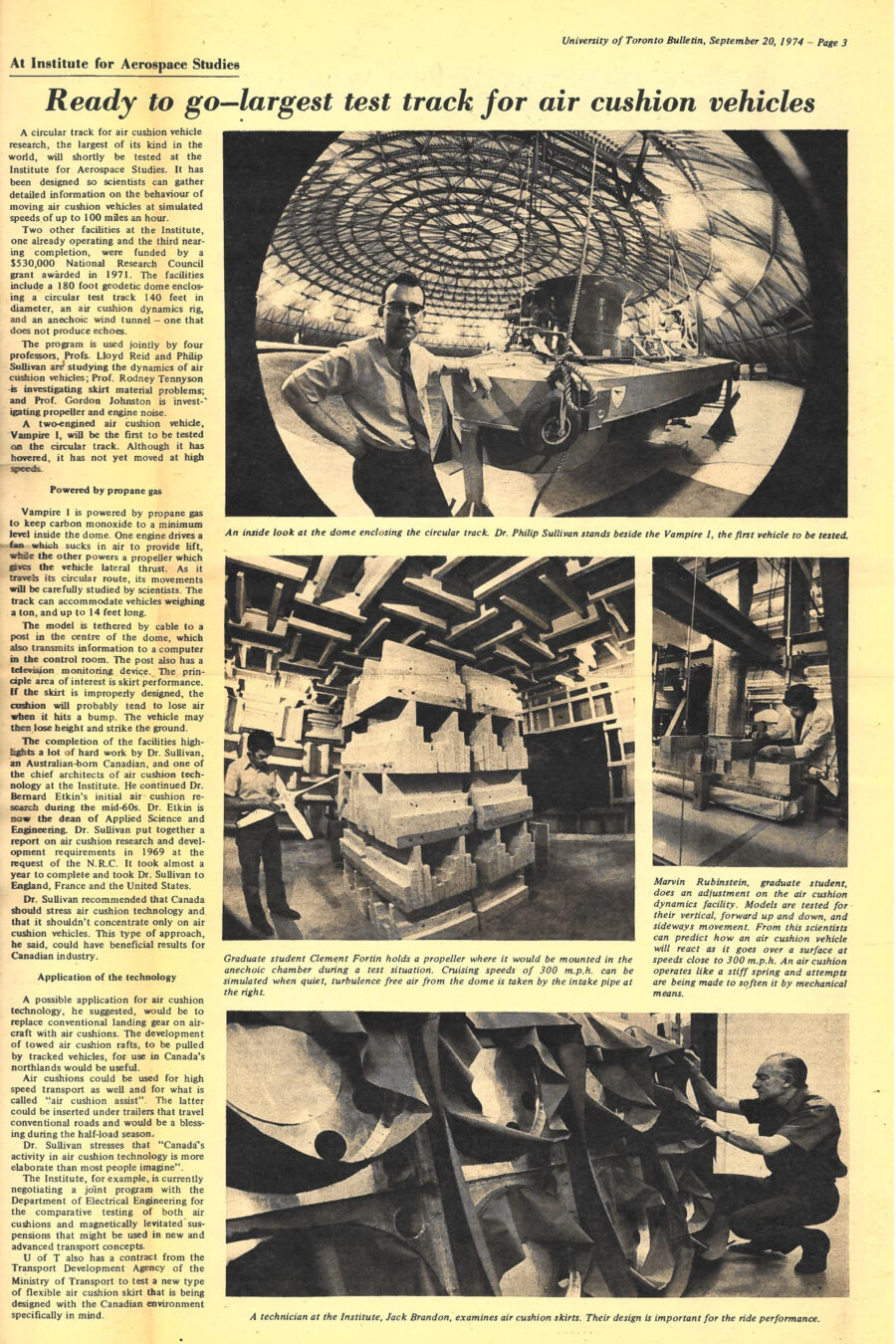

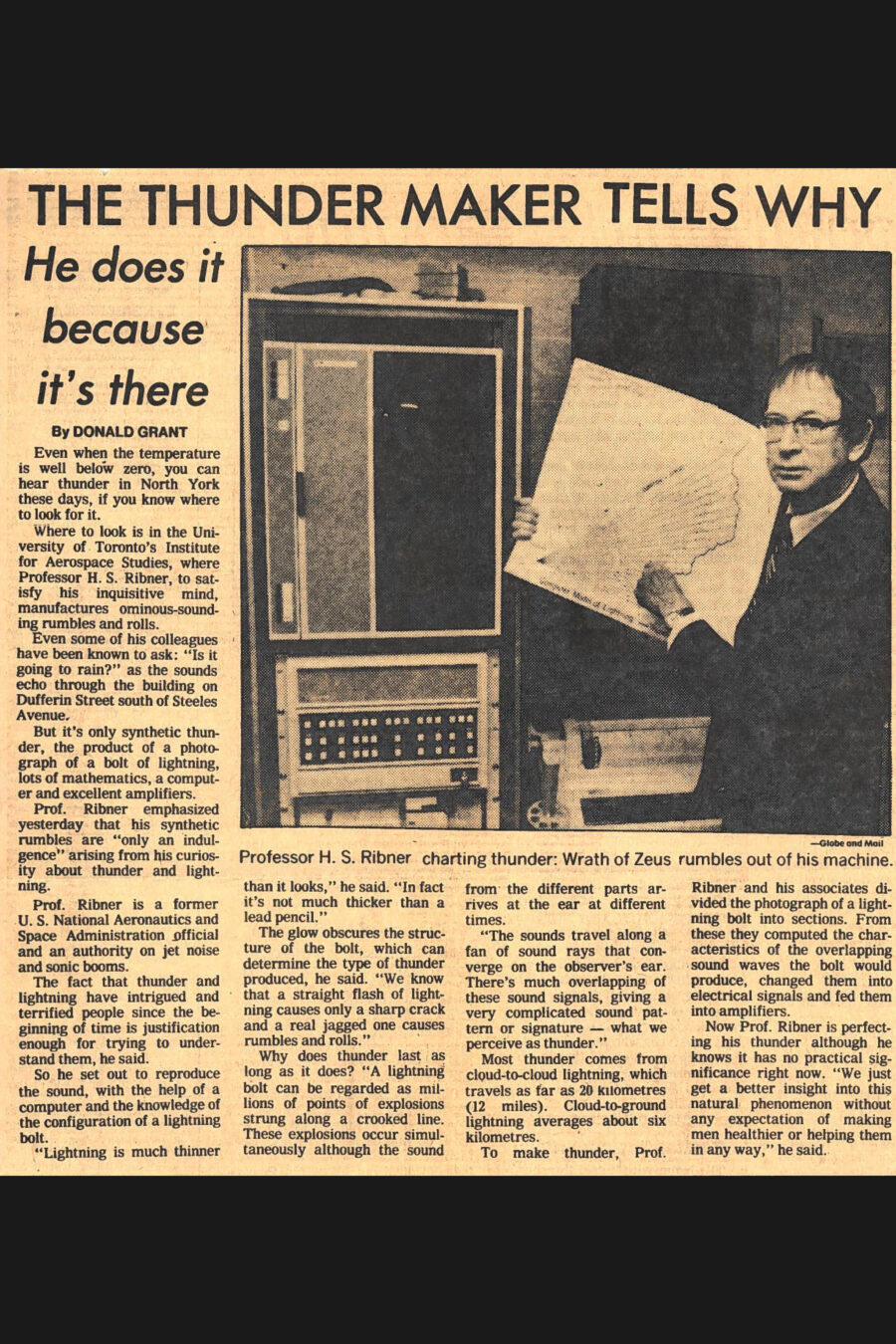

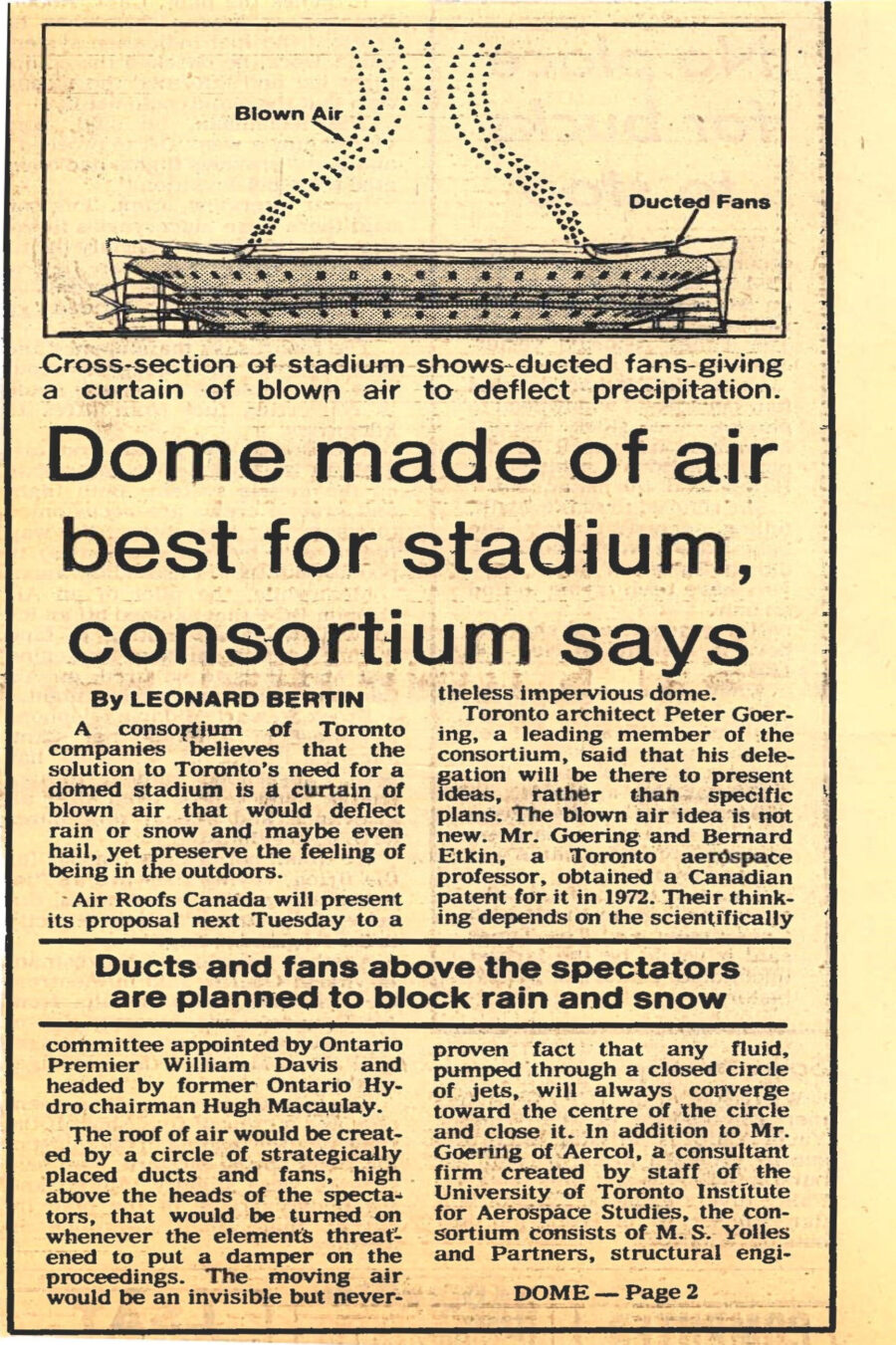

What if the SkyDome had begun as the AirDome?

1982

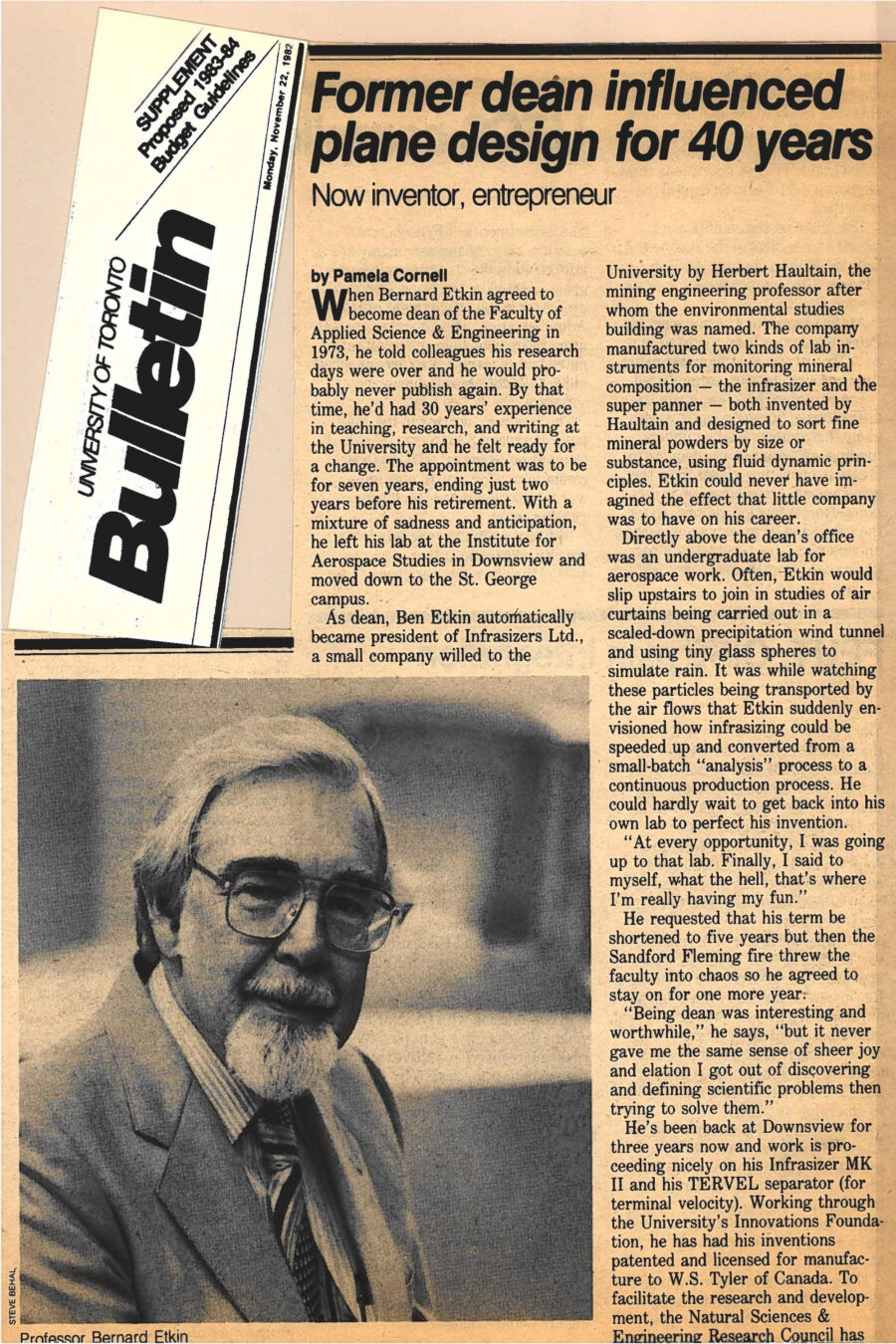

Professor Bernard Etkin always an innovator throughout his career.

1984

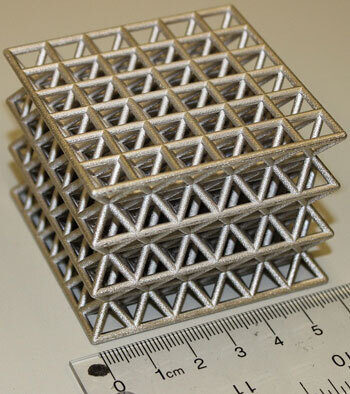

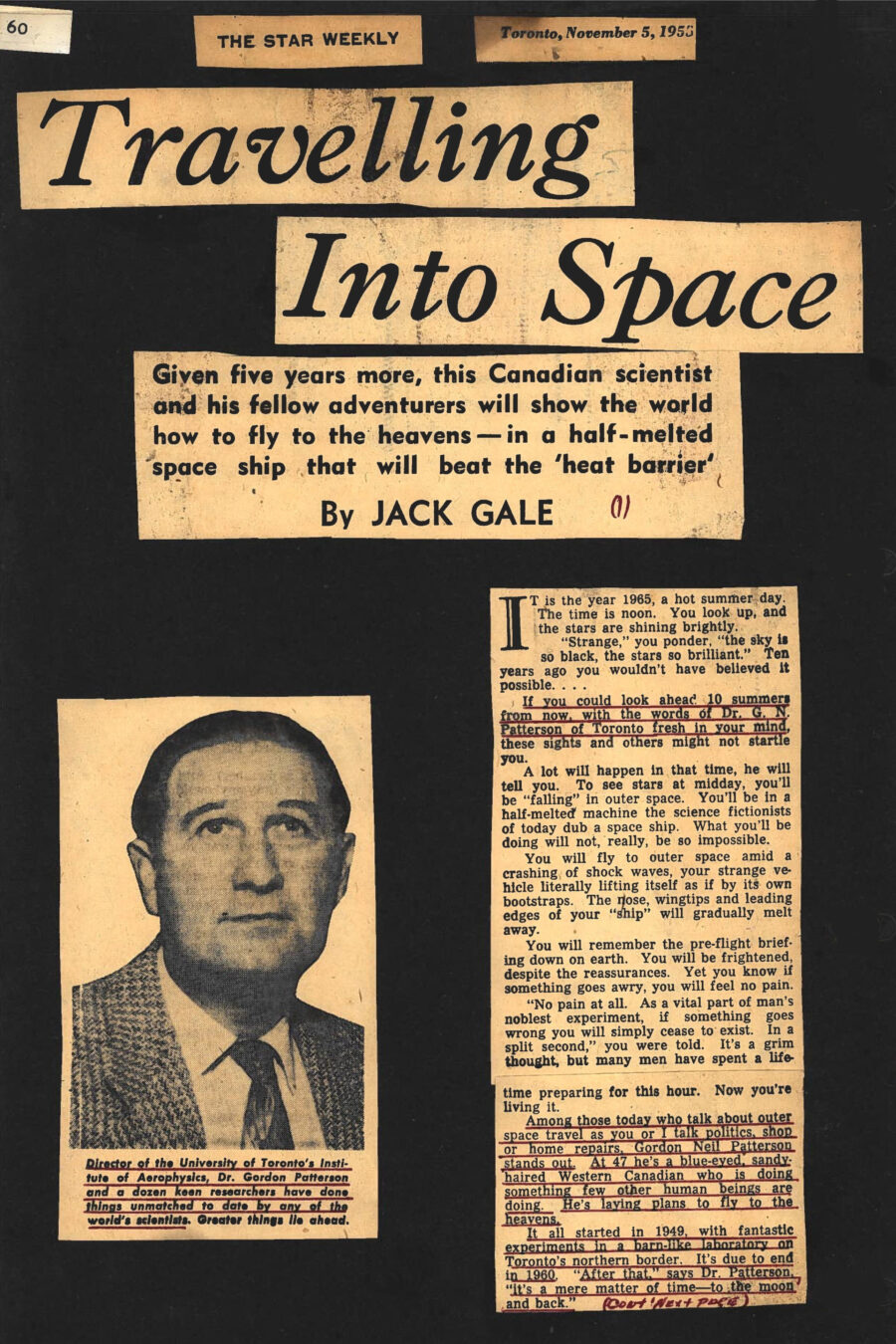

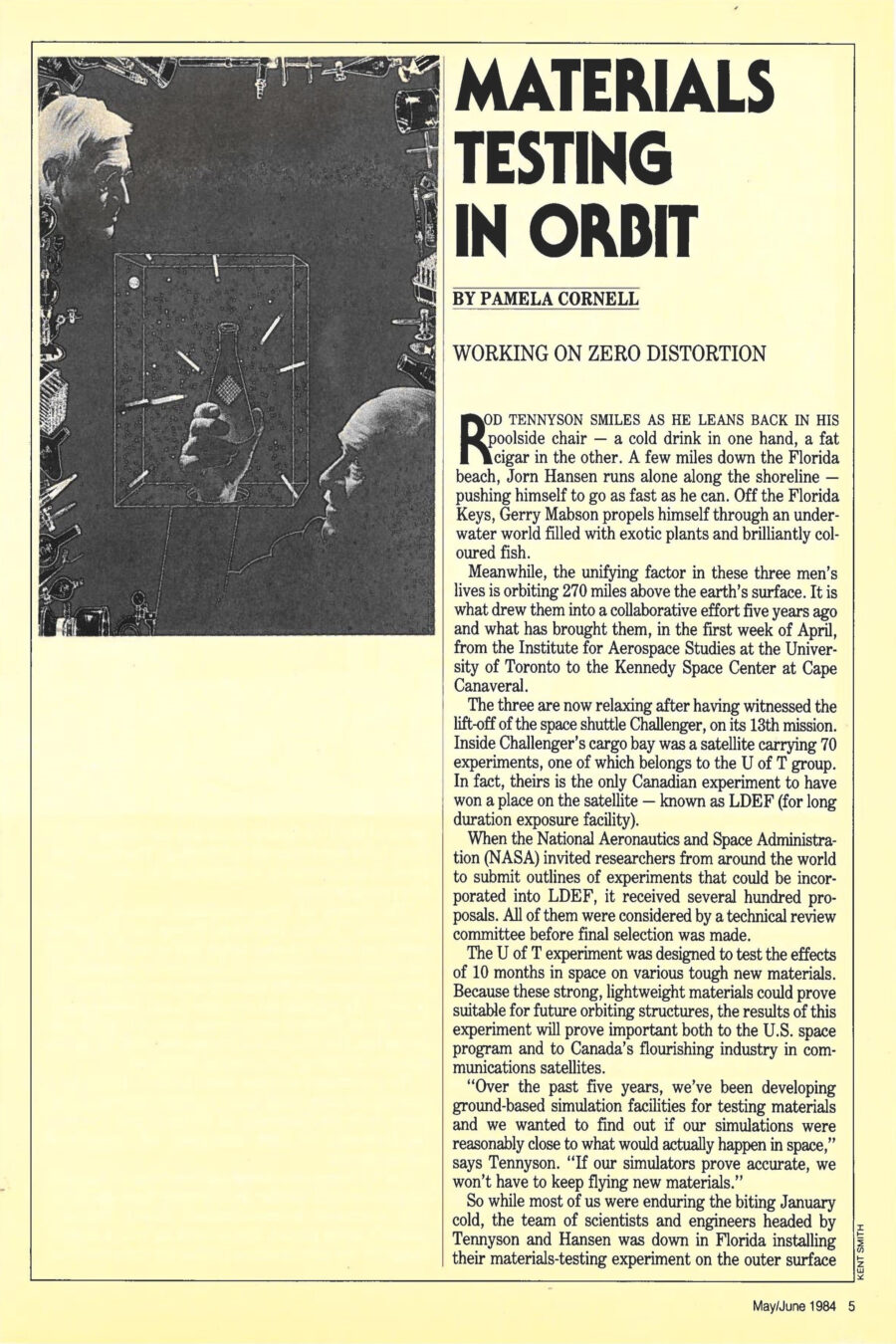

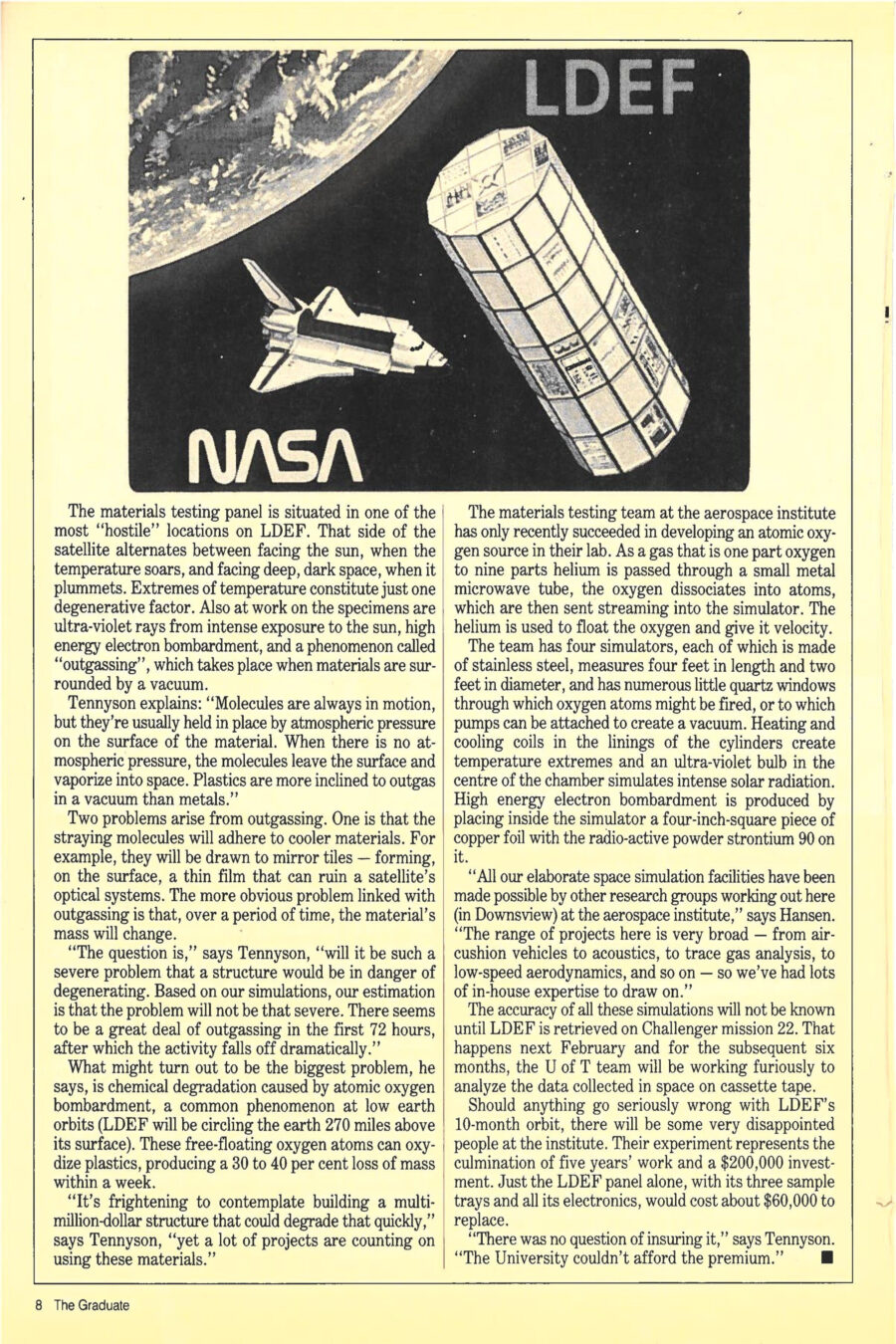

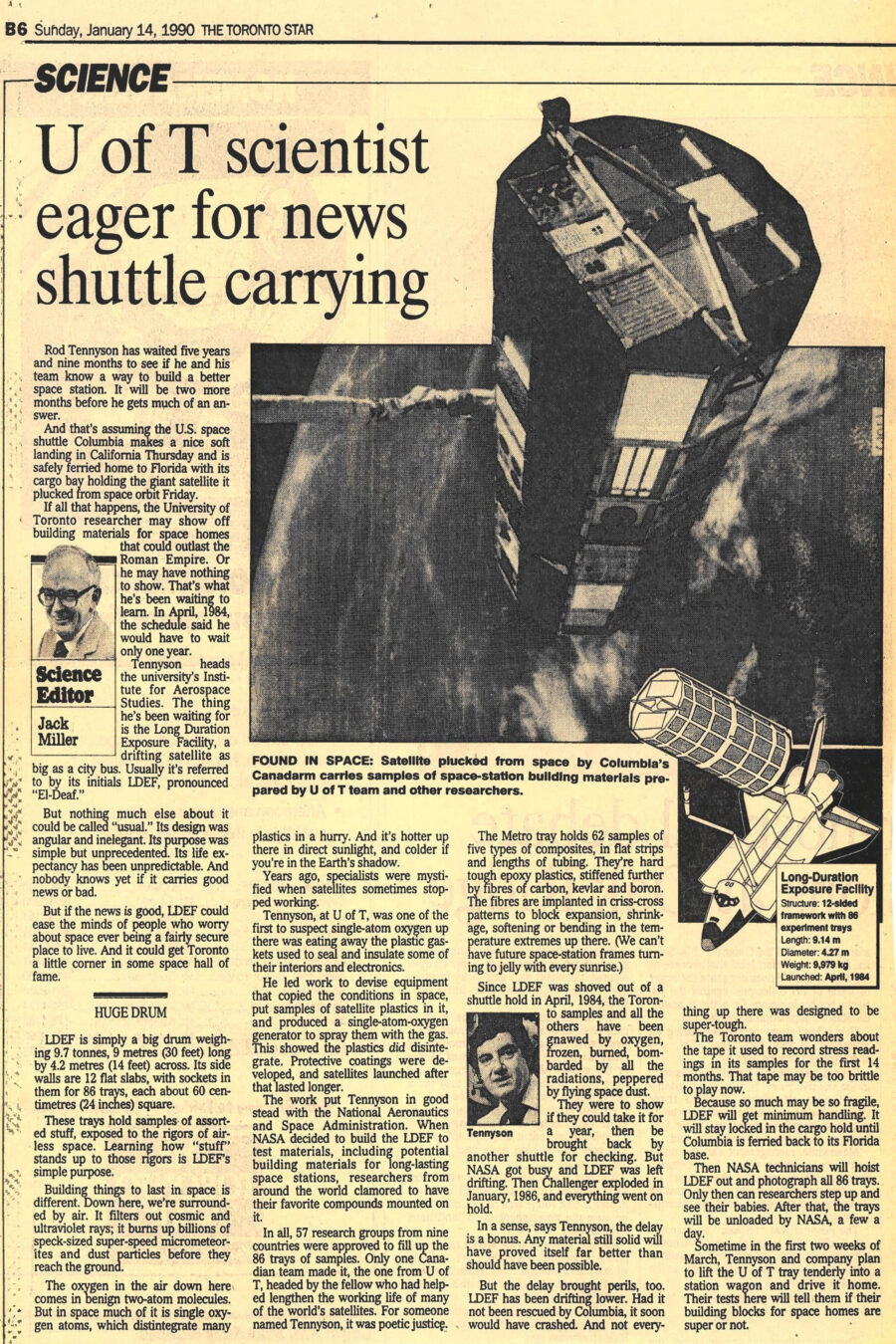

Testing materials on earth and in space.

1987

Professor Hughes mimics structural stress in space with Daisy.

1988

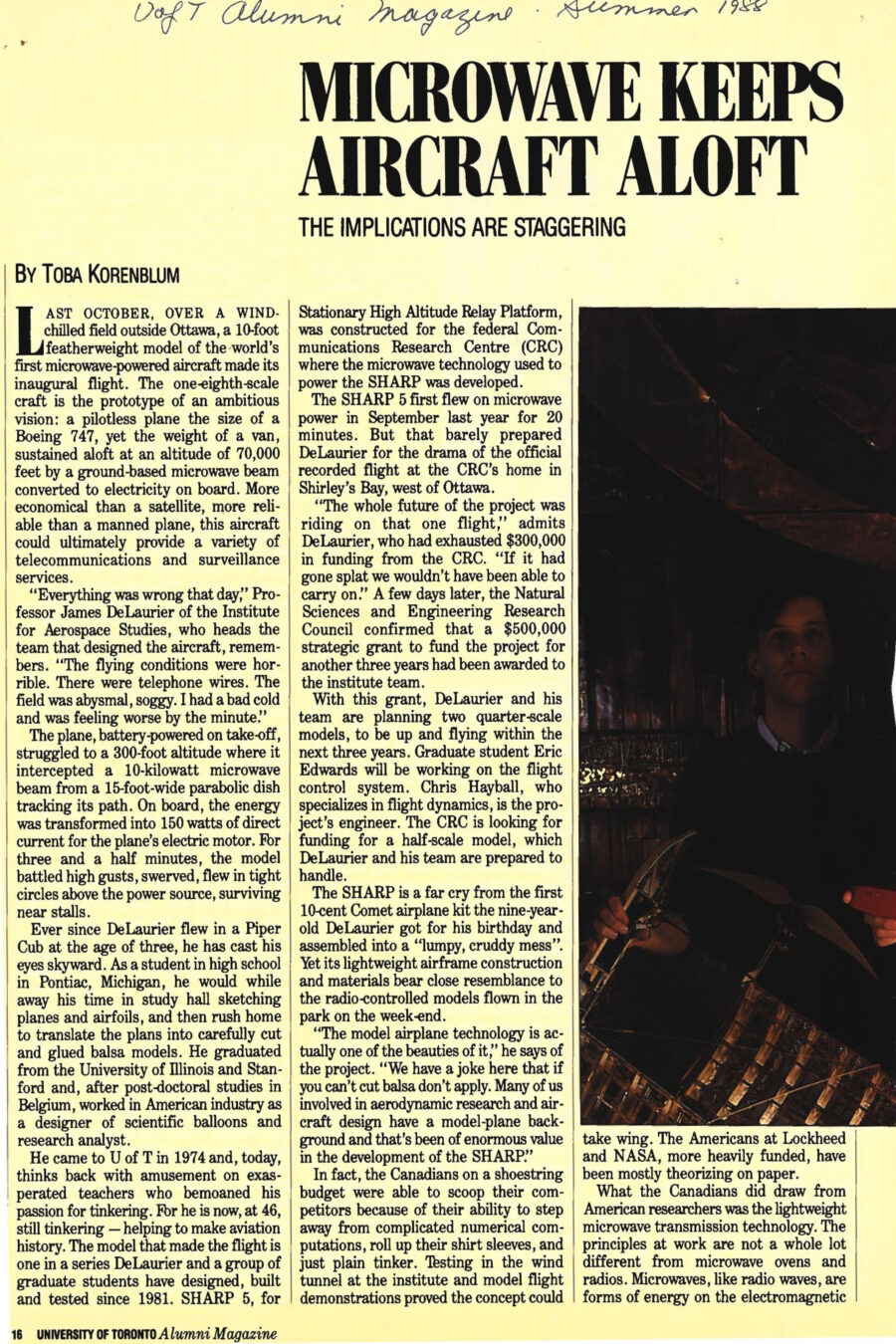

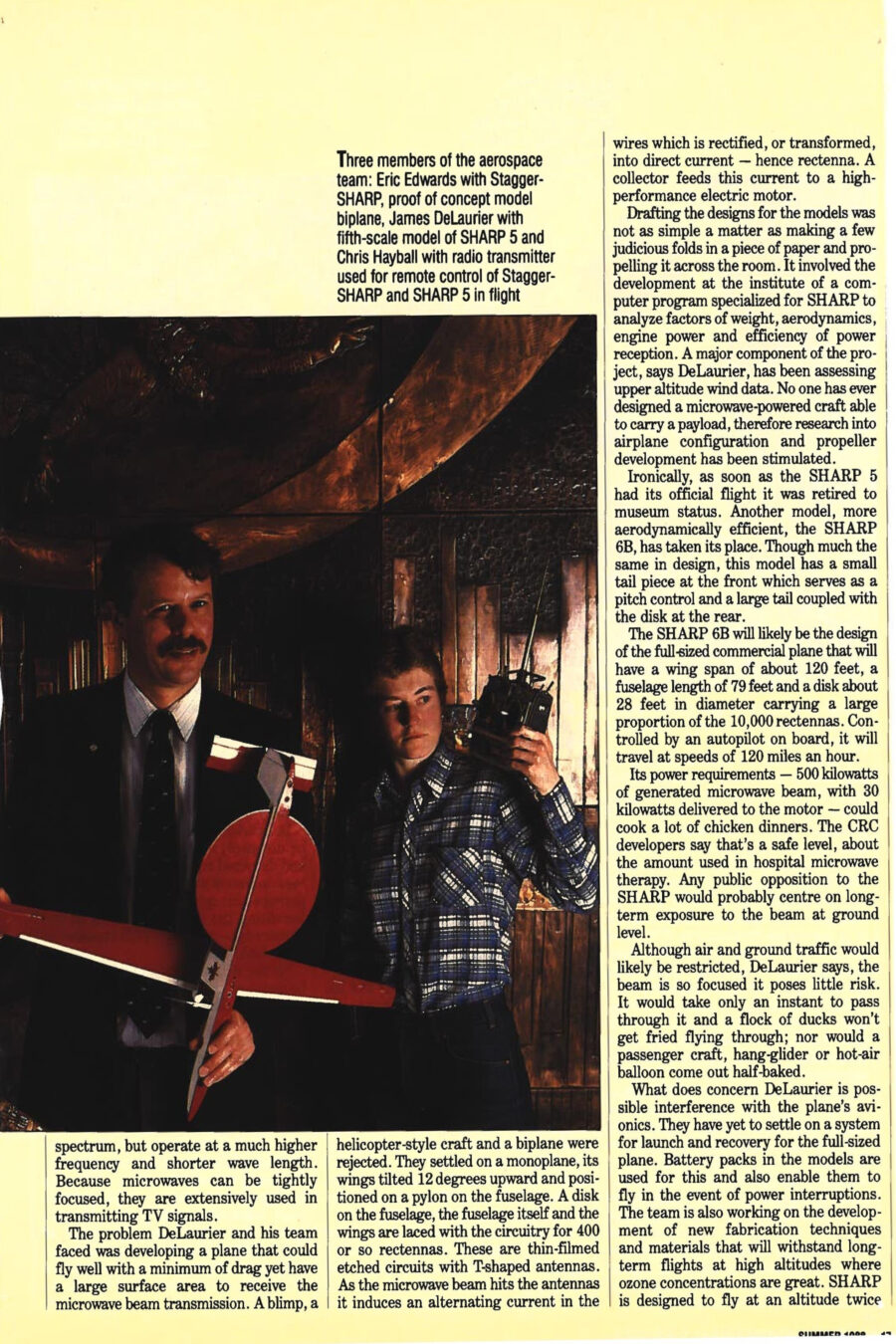

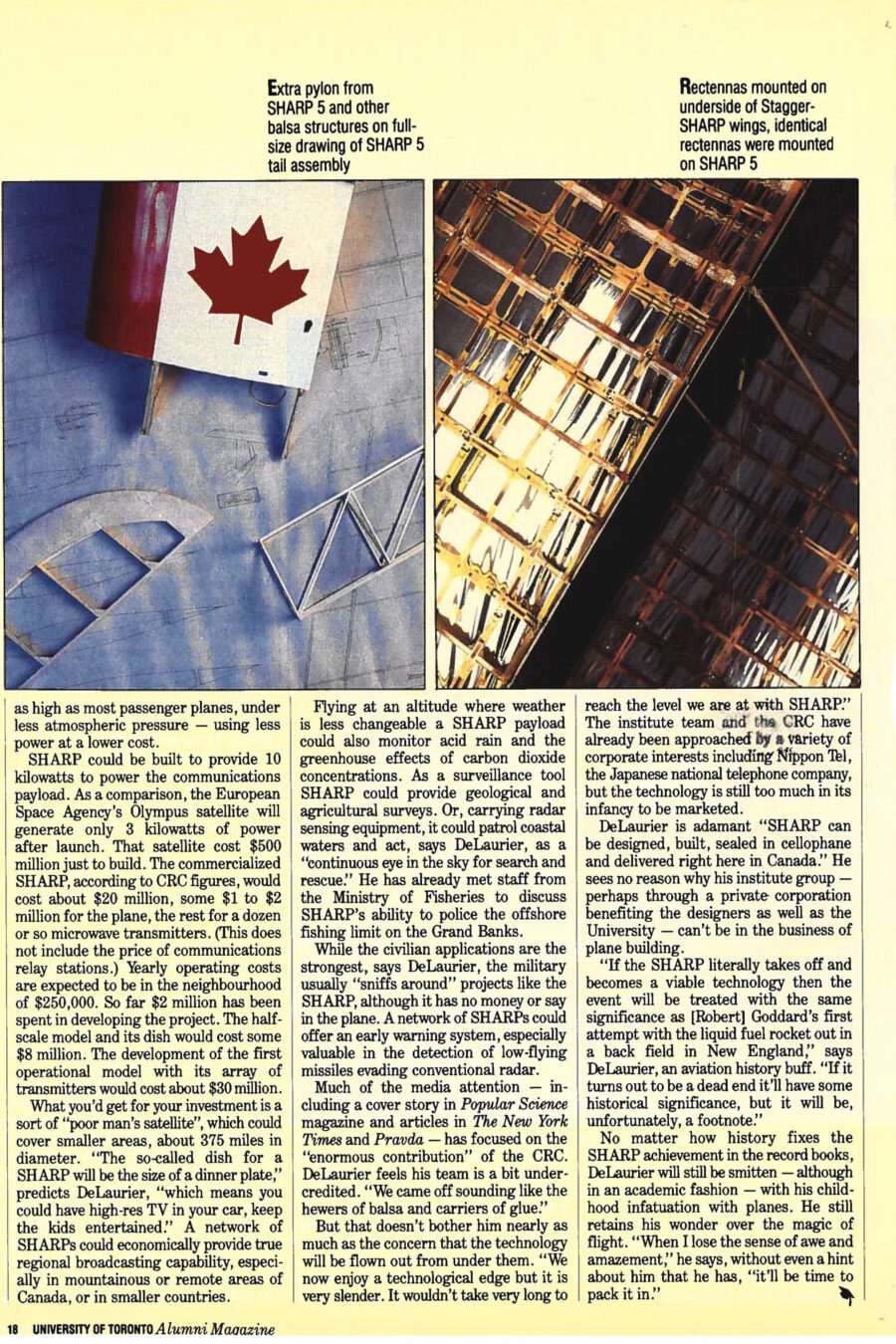

Professor DeLaurier harnesses microwaves for flight.

1989

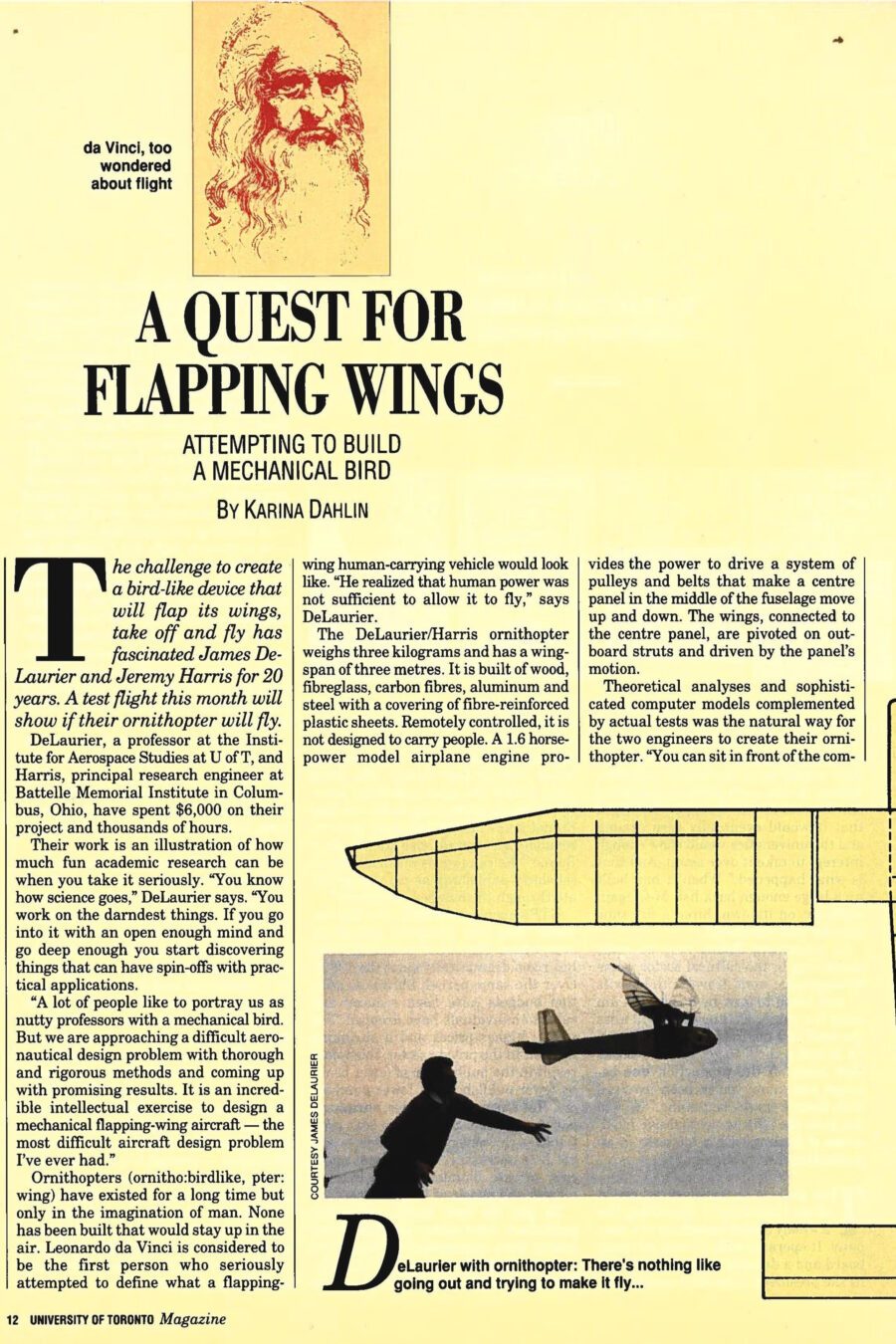

Professor DeLaurier's quest for mechanical flapping wings.

1990s

1990

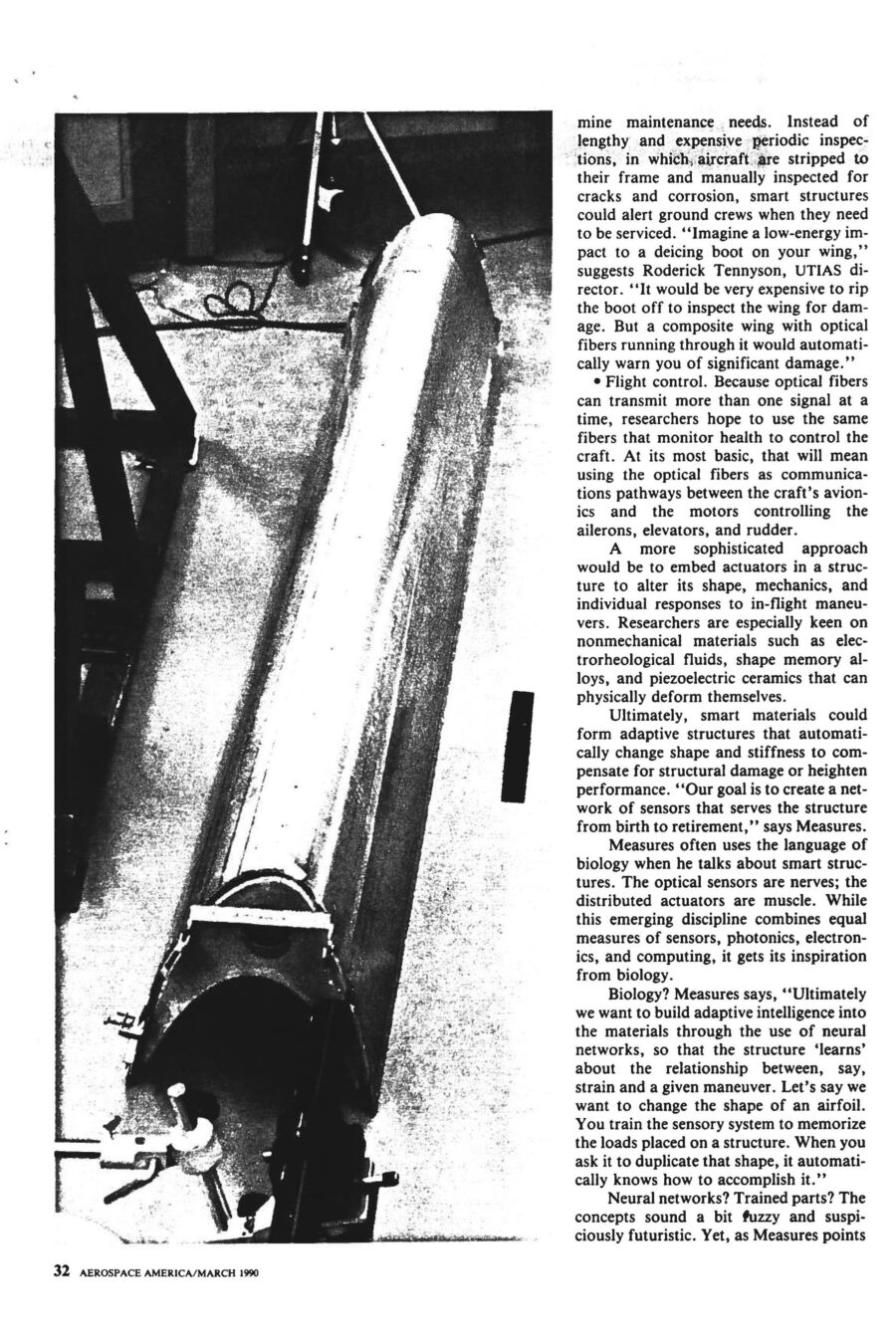

Professor Measures and smart materials. [Reprinted by permission of the American Institute of Aeronautics and Astronautics, Inc.]

1992

Professor DeLaurier's ornithopter takes flight!

1995

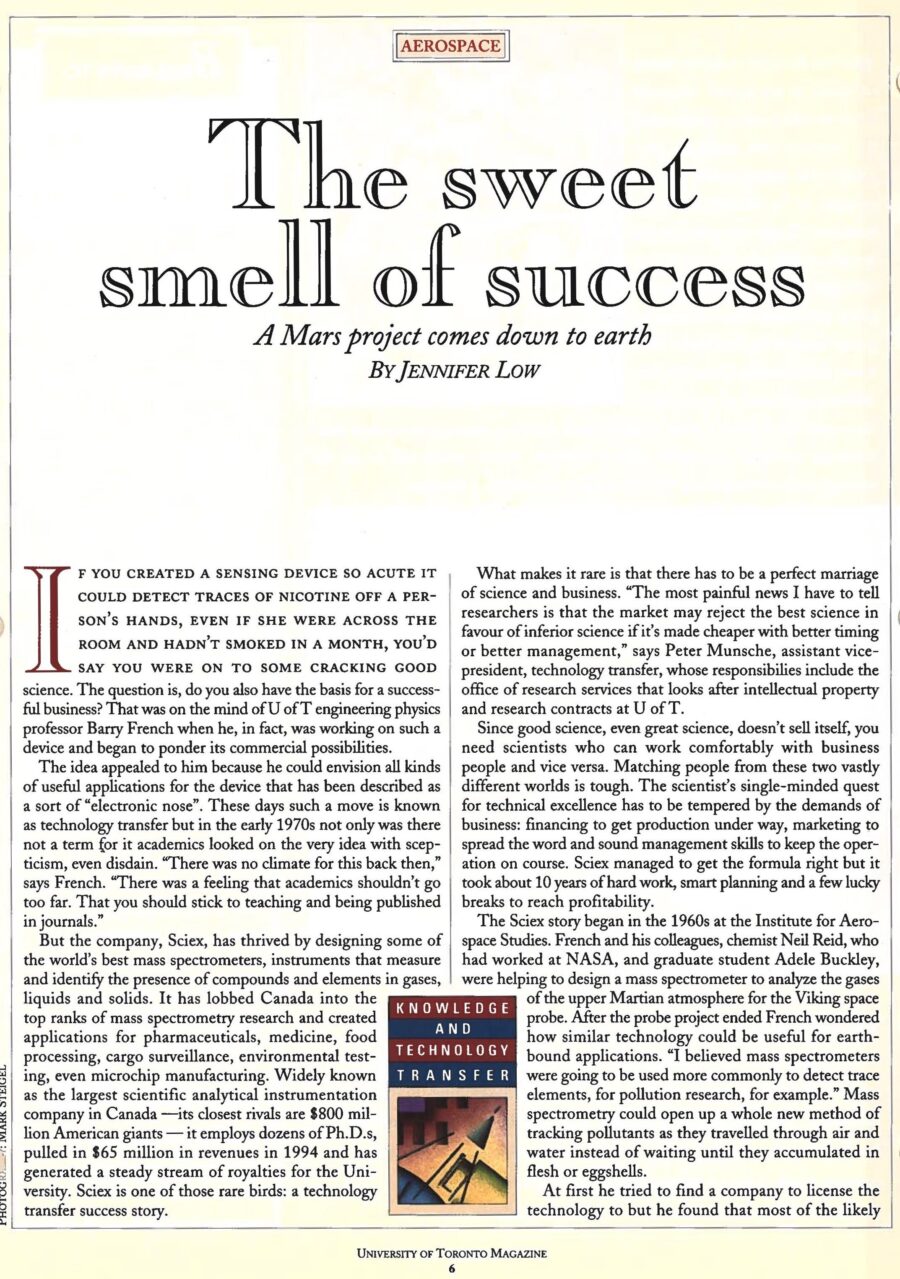

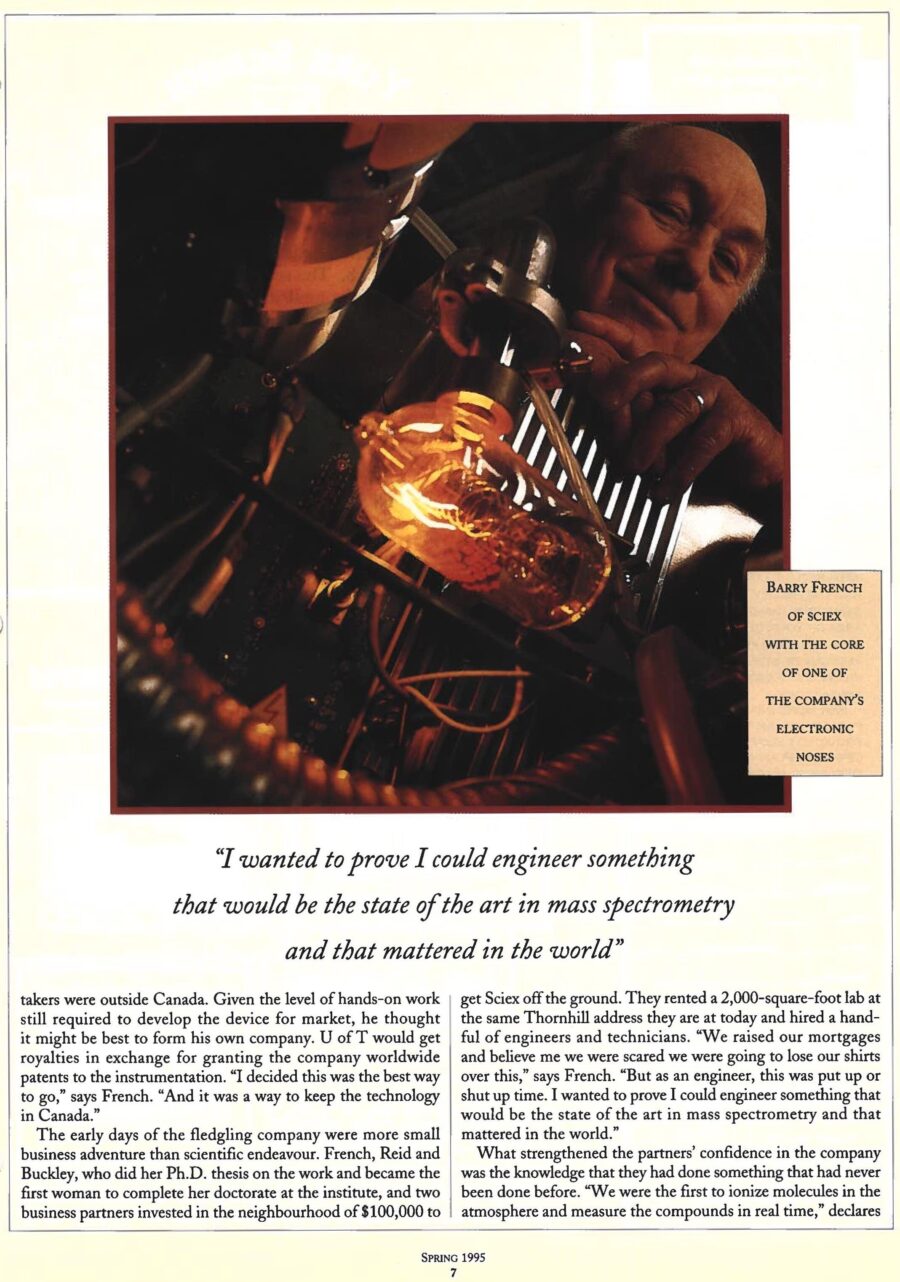

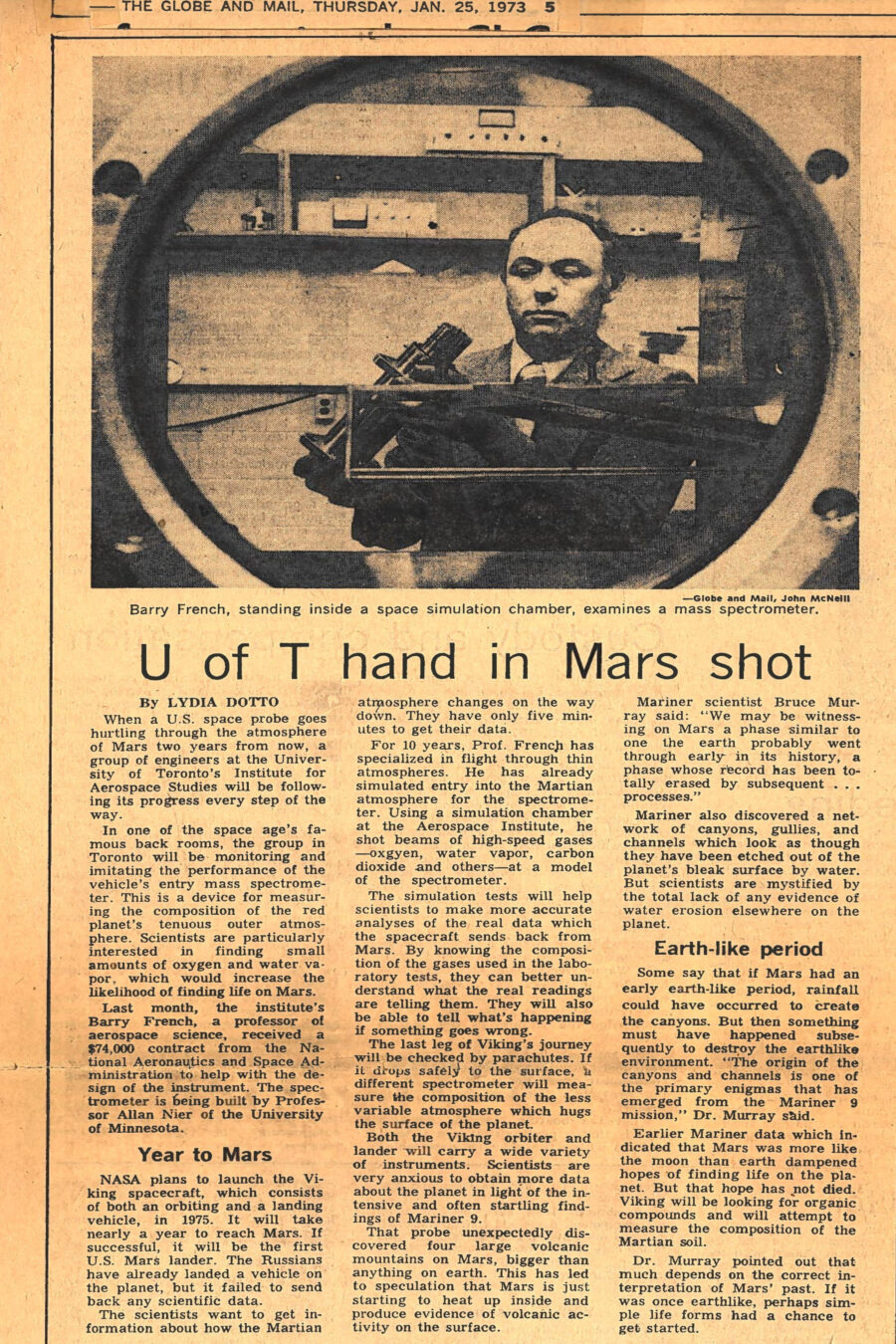

Mars project launches Sciex success.

2000s

2010s

2011

Professors Zingg and Gülder are researching sustainable aviation, through novel plane designs and the use of alternative fuels

2011

Professor DeLaurier launches inflatable, solar-powered plane for cargo missions to remote regions

2015

Take flight with Professor Zingg and his unconventional thinking on environmentally sensitive aircraft design

2016

Professors Craig Steeves and Philippe Lavoie strive to make aviation more sustainable with lightweight structures and "smart skin"

2016

Here Come the Robots - Professor Angela Schoellig appears on Steve Paikin's The Agenda on TVO

2016

Professor Tim Barfoot's visual teach and repeat technique enables mobile robots to drive themselves

2017

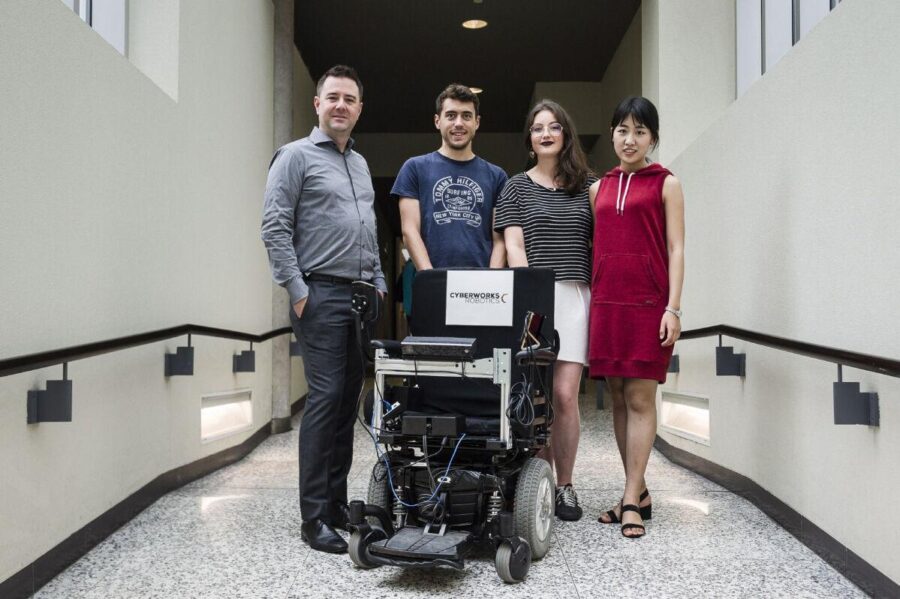

Prof. Jonathan Kelly collaborates with Cyberworks Robotics to create a self-driving, autonomous wheelchair

2017

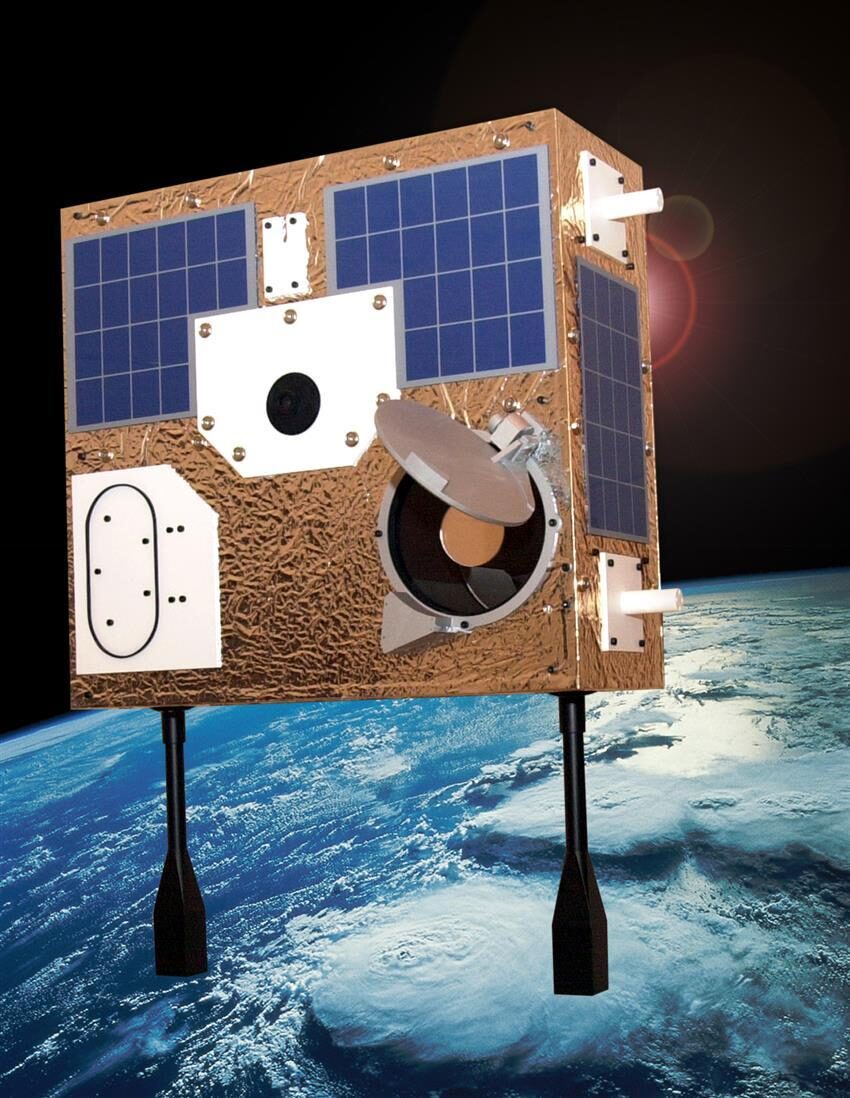

UTIAS Space Flight Laboratory builds microsatellite that deploys first-of-kind Yagi antenna for VHF data exchange from space

2018

Students from UTIAS’s Space Flight Laboratory Win Awards at Small Satellite Conference

2020s

2021

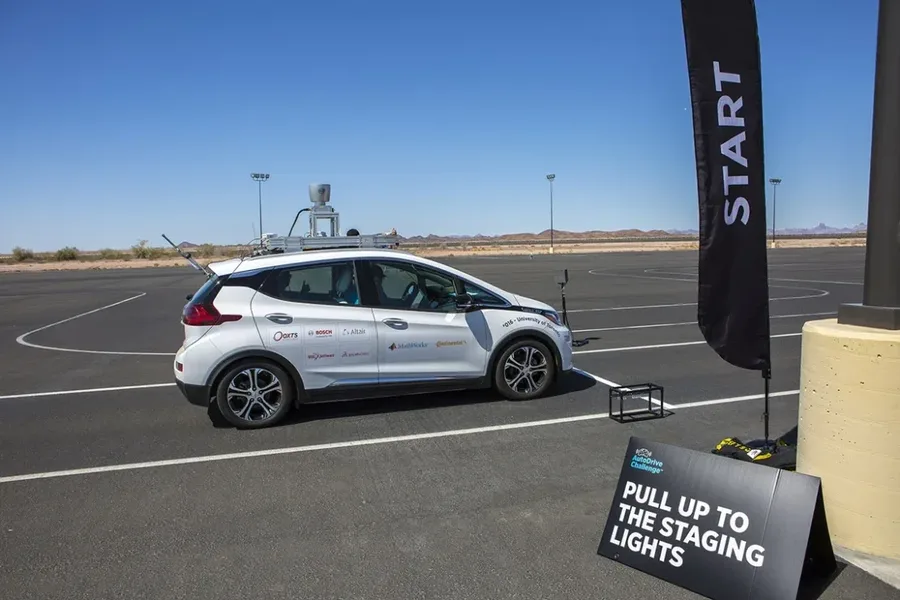

AutoDrive Challenge™: U of T Engineering places first for the fourth straight year

2022

Professor Tim Barfoot and a team including Dr. Hugues Thomas (pictured) design socially aware robots to move safely around people

2022

Another top prize for aUToronto in the first competition of the AutoDrive Challenge™ II

2024

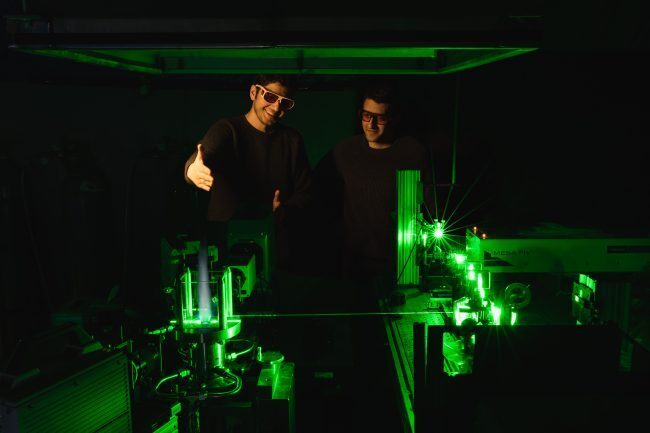

Professor Swetaprovo Chaudhuri partners with Siemens Energy to tackle sustainable energy production

![Magazine clipping from University of Toronto Alumni Magazine, Autumn 1987

Headline: Kicking up Daisy: Peter Hughes’ contraption (which vaguely resembles the flower) mimics the vibrations and stresses that will be imposed on huge structures in space

Byline: Lydia Dotto

Photo: Professor Hughes, wearing a suit and tie, stands before the criss-crossing radial struts of Daisy.

Asking a group of scientists what space is like puts one in mind of the story about the blind men and the elephants. Everyone “sees” something different. A life support expert sees a harsh unforgiving environment that can kill a human being in minutes. A physiologist sees a more subtle but no less dangerous environment that can cause long-term health problems. A materials scientist sees an environment that can be exploited to make ultra-pure drugs, crystals and semiconductors.

One of the ways Peter Hughes sees space is as mathematical equations that define the position and motions of large structures in space. And he sees sleeping lions and restless tigers that need taming. Hughes, who is the University of Toronto’s Cockburn professor of engineering and a researcher at the Institute for Aerospace Studies, has built a device called Daisy that allows him to study in the laboratory the best methods for controlling and pointing large, flexible space structures such as antennae, sensors and solar panels. Examples of such structures include communications satellites and radar satellites used for remote sensing and surveillance. The research may also have some applications to the space station being built by the western world.

The need for this research has been prompted by the trend toward putting larger and larger structures in space – a trend that will be accelerated by the increasing use of shuttle-like vehicles and astronauts trained as “hard hats” to do assembly and construction work in space. Spacecraft of the future may be very large. Communications antennae may be as large as 150 to 200 metres in diameter, the size of a small city block. On earth, large usually equates with heavy, bulky and solid. Not so in space. In a zero-gravity environment, even very large structures are usually quite flimsy; many would collapse under their own weight on earth. Controlling such structures is no easy task, especially when pin-point accuracy is required, as in the case of a mobile communications satellite trying to beam signals to moving ships or aircraft. But flexible structures can be aggravatingly uncooperative. They bend, deform, vibrate, oscillate – and once they get going, they are hard to stop. Worse, if the control system is ineffective, these vibrations might escalate to the point of catastrophic instability resulting in serious damage to the structure.

This is where Daisy comes in. It’s not a wind tunnel. It does not physically resemble the space structures being studied. Instead, it consists of a circular array of metallic ribs radiating out from a base. (Its name is simply a whimsical reference to its vague high-tech resemblance to the petals of a flower.) What Daisy does do is emulate the behaviour of a space structure – the vibrations and motions that occur when the structure is subjected to forces by its control and pointing system. The same laws of motion apply on earth and in space, says Hughes. “We’re not pretending to test the ‘real’ structure, but we’re testing a structure that is behaving dynamically like the real structure.”

Each of Daisy’s two-metre aluminum ribs is attached to the circular base structure by a hinge that allows the rib to bob and weave freely in response to forces imposed on it. The ribs are connected to each other so the structure resembles the dish of an antenna. One of the ribs is equipped with a small thruster and a sensor to measure acceleration. Jogging the structure sets up slow, long-lasting vibrations that mimic behaviour of a much larger flexible space structure.

These studies provide a relatively inexpensive intermediate step between modelling a structure’s behaviour with computers and testing a prototype in space. Jumping straight from mathematical equations to hardware can result in “some rather expensive mistakes,” Hughes says.

The focus of the research is on the systems used to control space structures. While necessary – they point antennae and keep a satellite in proper orbit – they are also the major source of unwanted vibrations. Space is described as a harsh environment, but it is relatively benign in terms of the natural forces acting on structures. “The only thing bashing them around is the control system,” Hughes says.

There are three essential elements to the control system: the “eyes” or sensors that measure what the structure is doing; the “brain” or the computer that compares what the structure is doing and what it’s supposed to be doing, and issues commands to correct discrepancies; and the “muscle” or actuators such as motors, reaction wheels or thrusters, that respond to the computer’s commands. Control systems may over-correct. Flexible spacecraft vibrate in several different modes (directions) and correcting for one mode can start unwanted vibrations in others. And, due to light damping, over-correction can exacerbate the vibration problems. Control problems are getting worse because space structures are not only getting larger and flimsier, but the requirements for faster and finer control and pointing accuracy are becoming increasingly stringent.

Strategic Defense Initiative (SDI) technology is perhaps the ultimate case in point. Hughes says that while Daisy does not involve any work on SDI, the results will be available in the open literature and “could be” of some interest to SDI researchers. He adds that SDI represents an “extraordinarily difficult” control problem and “the whole thing only makes sense to [President Ronald] Reagan.”

Daisy is being used to study all three elements of the control system and Hughes hopes the research will lead to the development of new sensors and actuators for large space structures. The project has been funded by $600,000 in federal grants and contracts. The hardware was built by Dynacon Enterprises, a company founded by Hughes, under contract to the Department of Communications. The work of Hughes and his graduate students, and the cost of electronic equipment is being funded by a grant from the Natural Sciences and Engineering Research Council.

Through Dynacon, Hughes is also involved in two projects related to the international space station being built by the United States, Canada, Europe and Japan. The station, which will cost $20 billion US or more, is scheduled to go into operation in a 500-kilometre orbit n the mid-1990s. Canada’s contribution will be a Mobile Servicing System (MSS), an advanced computerized manipulator system that will help in the assembly and construction of the station structure and then be used for cargo-handling, servicing and refurbishment. Spar Aerospace is building the MSS. They’ve begun with building a sophisticated computer that will aid in the design and testing of the MSS. Dynacon has been sub-contracted to develop equations of motion on which the simulator’s computer programs will be based, including dynamic situations such as docking space shuttles to the station and using the manipulators to grapple cargo and to release satellites and other payloads into space.

Controlling the motion of manipulators is tricky. A manipulator must be capable of releasing a payload without imparting unwanted motions to it, and it must be able to grab large, multi-million dollar pieces of equipment without damaging them or itself. Dynacon is also doing another project for the National Research Council, involving studying an advanced manipulator that Hughes calls a “Trussarm.” This type of manipulator would have a lattice or truss structure not unlike those found on large construction cranes on earth. This is a very stable structure possessing great strength for its weight, so it’s expected to be very useful in space. Trussarm would be uniquely hinged in such a way that the arm could twist and turn and even curl around obstacles and into nooks and crannies, effective but posing many control problems. At present, there are no plans to build the device, but Hughes says “the Japanese are working on this like crazy.”](https://75.utias.utoronto.ca/images/_full/1-Hughes-Kicking-up-Daisy.jpg)

![Magazine clipping from University of Toronto Alumni Magazine, Autumn 1987

Headline: Kicking up Daisy: Peter Hughes’ contraption (which vaguely resembles the flower) mimics the vibrations and stresses that will be imposed on huge structures in space

Byline: Lydia Dotto

Photo: Professor Hughes, wearing a suit and tie, stands before the criss-crossing radial struts of Daisy.

Asking a group of scientists what space is like puts one in mind of the story about the blind men and the elephants. Everyone “sees” something different. A life support expert sees a harsh unforgiving environment that can kill a human being in minutes. A physiologist sees a more subtle but no less dangerous environment that can cause long-term health problems. A materials scientist sees an environment that can be exploited to make ultra-pure drugs, crystals and semiconductors.

One of the ways Peter Hughes sees space is as mathematical equations that define the position and motions of large structures in space. And he sees sleeping lions and restless tigers that need taming. Hughes, who is the University of Toronto’s Cockburn professor of engineering and a researcher at the Institute for Aerospace Studies, has built a device called Daisy that allows him to study in the laboratory the best methods for controlling and pointing large, flexible space structures such as antennae, sensors and solar panels. Examples of such structures include communications satellites and radar satellites used for remote sensing and surveillance. The research may also have some applications to the space station being built by the western world.

The need for this research has been prompted by the trend toward putting larger and larger structures in space – a trend that will be accelerated by the increasing use of shuttle-like vehicles and astronauts trained as “hard hats” to do assembly and construction work in space. Spacecraft of the future may be very large. Communications antennae may be as large as 150 to 200 metres in diameter, the size of a small city block. On earth, large usually equates with heavy, bulky and solid. Not so in space. In a zero-gravity environment, even very large structures are usually quite flimsy; many would collapse under their own weight on earth. Controlling such structures is no easy task, especially when pin-point accuracy is required, as in the case of a mobile communications satellite trying to beam signals to moving ships or aircraft. But flexible structures can be aggravatingly uncooperative. They bend, deform, vibrate, oscillate – and once they get going, they are hard to stop. Worse, if the control system is ineffective, these vibrations might escalate to the point of catastrophic instability resulting in serious damage to the structure.

This is where Daisy comes in. It’s not a wind tunnel. It does not physically resemble the space structures being studied. Instead, it consists of a circular array of metallic ribs radiating out from a base. (Its name is simply a whimsical reference to its vague high-tech resemblance to the petals of a flower.) What Daisy does do is emulate the behaviour of a space structure – the vibrations and motions that occur when the structure is subjected to forces by its control and pointing system. The same laws of motion apply on earth and in space, says Hughes. “We’re not pretending to test the ‘real’ structure, but we’re testing a structure that is behaving dynamically like the real structure.”

Each of Daisy’s two-metre aluminum ribs is attached to the circular base structure by a hinge that allows the rib to bob and weave freely in response to forces imposed on it. The ribs are connected to each other so the structure resembles the dish of an antenna. One of the ribs is equipped with a small thruster and a sensor to measure acceleration. Jogging the structure sets up slow, long-lasting vibrations that mimic behaviour of a much larger flexible space structure.

These studies provide a relatively inexpensive intermediate step between modelling a structure’s behaviour with computers and testing a prototype in space. Jumping straight from mathematical equations to hardware can result in “some rather expensive mistakes,” Hughes says.

The focus of the research is on the systems used to control space structures. While necessary – they point antennae and keep a satellite in proper orbit – they are also the major source of unwanted vibrations. Space is described as a harsh environment, but it is relatively benign in terms of the natural forces acting on structures. “The only thing bashing them around is the control system,” Hughes says.

There are three essential elements to the control system: the “eyes” or sensors that measure what the structure is doing; the “brain” or the computer that compares what the structure is doing and what it’s supposed to be doing, and issues commands to correct discrepancies; and the “muscle” or actuators such as motors, reaction wheels or thrusters, that respond to the computer’s commands. Control systems may over-correct. Flexible spacecraft vibrate in several different modes (directions) and correcting for one mode can start unwanted vibrations in others. And, due to light damping, over-correction can exacerbate the vibration problems. Control problems are getting worse because space structures are not only getting larger and flimsier, but the requirements for faster and finer control and pointing accuracy are becoming increasingly stringent.

Strategic Defense Initiative (SDI) technology is perhaps the ultimate case in point. Hughes says that while Daisy does not involve any work on SDI, the results will be available in the open literature and “could be” of some interest to SDI researchers. He adds that SDI represents an “extraordinarily difficult” control problem and “the whole thing only makes sense to [President Ronald] Reagan.”

Daisy is being used to study all three elements of the control system and Hughes hopes the research will lead to the development of new sensors and actuators for large space structures. The project has been funded by $600,000 in federal grants and contracts. The hardware was built by Dynacon Enterprises, a company founded by Hughes, under contract to the Department of Communications. The work of Hughes and his graduate students, and the cost of electronic equipment is being funded by a grant from the Natural Sciences and Engineering Research Council.

Through Dynacon, Hughes is also involved in two projects related to the international space station being built by the United States, Canada, Europe and Japan. The station, which will cost $20 billion US or more, is scheduled to go into operation in a 500-kilometre orbit n the mid-1990s. Canada’s contribution will be a Mobile Servicing System (MSS), an advanced computerized manipulator system that will help in the assembly and construction of the station structure and then be used for cargo-handling, servicing and refurbishment. Spar Aerospace is building the MSS. They’ve begun with building a sophisticated computer that will aid in the design and testing of the MSS. Dynacon has been sub-contracted to develop equations of motion on which the simulator’s computer programs will be based, including dynamic situations such as docking space shuttles to the station and using the manipulators to grapple cargo and to release satellites and other payloads into space.

Controlling the motion of manipulators is tricky. A manipulator must be capable of releasing a payload without imparting unwanted motions to it, and it must be able to grab large, multi-million dollar pieces of equipment without damaging them or itself. Dynacon is also doing another project for the National Research Council, involving studying an advanced manipulator that Hughes calls a “Trussarm.” This type of manipulator would have a lattice or truss structure not unlike those found on large construction cranes on earth. This is a very stable structure possessing great strength for its weight, so it’s expected to be very useful in space. Trussarm would be uniquely hinged in such a way that the arm could twist and turn and even curl around obstacles and into nooks and crannies, effective but posing many control problems. At present, there are no plans to build the device, but Hughes says “the Japanese are working on this like crazy.”](https://75.utias.utoronto.ca/images/_full/2-Hughes-Kicking-up-Daisy_page_2.jpg)

![Newspaper clipping from University of Toronto Bulletin, April 23, 1990

Headline: Space materials return home

Byline: Jane Stirling

Photo 1: Professor Tennyson looks over an array of metal tubes mounted together.

Caption: Professor Rod Tennyson points out some of the nicks and abrasions on the surface of his samples. Behind him is the data acquisition system custom made at the Institute.

Photo 2: The drum-shaped cylinder of the LDEF satellite, secured in a NASA hangar.

Caption: At left is the drum-shaped LDEF satellite equipped with various research projects. The arrow points out the location of the U of T experiment.

With his face barely two inches from a tray of oddly shaped articles, Professor Rod Tennyson, director of the Institute for Aerospace Studies, enthusiastically scrutinizes the tubular and flat objects. He is looking for somethings barely visible to the naked eye. “Do you see this tiny hole in the aluminum?” he asks. “That was caused by a micrometeoroid hit.”

The items he is examining spent almost six years in space aboard a National Aeronautics & Space Administration (NASA) satellite called the Long Duration Exposure Facility (LDEF). The satellite carrying 72 experiments, including the University of Toronto’s (the only Canadian one), was returned to earth in January aboard the space shuttle Columbia. The original retrieval date had been scheduled for 1985 but recovery was delayed when the United States grounded its shuttle flights after the explosion of the Challenger.

Tennyson, Professor Jorn Hansen of Aerospace and former graduate student Gerry Mabson (now an engineer practising in the United States) had almost given up hope of ever seeing their experiment again. Gravity would have pulled the satellite to earth and fiery death within weeks of its retrieval.

The university researchers won a spot on the satellite in an international competition run by the United States space agency in the early 1980s. NASA is hoping to find appropriate construction materials for its proposed $40 billion space station due to be launched in the mid-1990s.

The University’s experiment consisted of three trays of 67 tubular and flatplate samples made with either graphite (carbon) or modified nylon fibres and bonded with different types of epoxy glue. The researchers were hoping to determine which fibre-epoxy combination would best withstand an extended stay in space.

A fibre-constructed station would be much lighter than an aluminum one and would therefore be easier to launch, Tennyson said. Fibres can also be layered, which helps to decrease the expansion and contraction that occurs in space with its extremes of temperature. “We were looking for zero distortion capability.”

Early analysis indicates none of the samples would be suitable without some sort of protective coating, he said. By examining the surfaces of the samples, Tennyson has discovered small meteoroid holes. The satellite itself probably received about 8,000 such hits, NASA estimates. Some of the larger holes are half a centimetre in diameter – the meteoroids that caused these could kill an astronaut. The smaller ones that hit the University’s experiment caused abrasions and cracking.

The collision areas provide entry for atomic oxygen to work underneath the coating and corrode from beneath. Early estimates by the University of Toronto laboratory suggest that one-fifth of the half-millimetre-thick composites may have been eaten away by oxygen. If the University of Toronto experiment had been at the front of LDEF, the effect of atomic corrosion would have been greater, Tennyson said. However, the samples were situated 90 degrees away from the leading edge of the drum-shaped satellite.

Coating the samples with a silicone-like varnish might prevent corrosion to a certain extent. The University of Toronto scientists, in conjunction with the Canadian Space Agency and l’Ecole Polytechnique in Montreal, will test the effectiveness of coatings by sending up another payload on the next NASA launch in August.

“Coatings are not the answer but they’ll buy us a number of years,” Tennyson said. “We think we can enhance the lifetime [of the space station] by a factor of two with coatings but this does not take into account the meteoroids – we are uncertain what will happen if they cause a great deal of damage.”

NASA plans to operate the space station for thirty years but repairs due to corrosion and meteroids will probably be necessary after ten years, Tennyson said.

While atomic oxygen seems to be the dominant problem, radiation is also a concern for researchers. The unfiltered ultraviolet rays caused chemical breakdowns and discolouration on the surface of the samples. However another type of radiation, high-energy electrons that can break chemical bonds, could prove even more damaging by causing cracks in the material. The researchers will not know how extensive this damage is until they start their tests.

An added feature of the experiment was a custom-made data acquisition system that measured, among other things, the temperature in space and the thermal distortion of the samples. The system, which uses a tape cassette to record information, automatically turned on every sixteen hours for two seconds. “NASA was not convinced it would work,” Tennyson said, “but it worked perfectly.” Similar equipment in the United States costs $300,000 and Tennyson believes he can market the University of Toronto model for about $70,000.

For the next year, Tennyson and his team will be involved in conducting tests on the samples. Using an optical microscope, they will be measuring the angle at which the atomic oxygen hit their experiment. From these results NASA will be able to calculate the exact orientation of the satellite in space – an important detail in assessing the results from the other experiments.

In another test, the University of Toronto researchers will place the data acquisition package in the institute’s space simulator to compare and possibly extrapolate the results gained aboard the LDEF. They will also be measuring the exact amount of mass that was lost due to atomic oxygen corrosion and the change in chemical properties.

While testing is just getting under way this week, Tennyson has already made one interesting observation. Large chunks of a substance resembling tin foil were discovered inside some of the open-ended tubes. The shiny flakes were all that remained from aluminum-backed Mylar sheets attached to other experiments. The sheets themselves, used for thermal control in space, had disintegrated.

Tennyson’s findings indicate that Mylar is not durable enough to protect instruments in space. While NASA had suspected this, the University of Toronto experiment “is the first to bring back such graphic results.”](https://75.utias.utoronto.ca/images/_full/1-Tennyson-Space-materials-return-home.jpg)